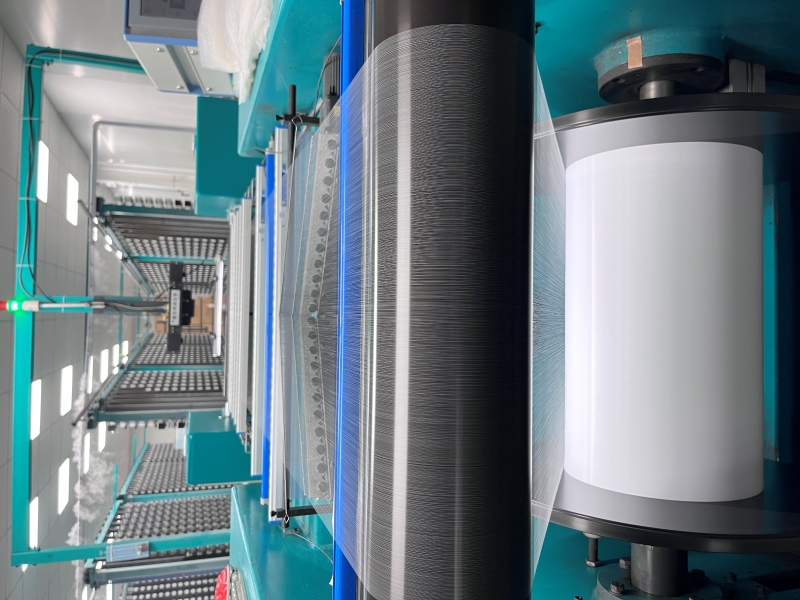

Spandex Warping Machine is for warping spandex or Lycra yarn on beams. Our AZE318 model quality spandex warping machine is equipped with a vertical creel driven by high-performance servo motors, and equipped with an extremely precise laser detector, and other devices to ensure the yarn tension stability. Spandex Warping machine is widely used for tricot machines to run fabric with nylon yarn. We are a spandex warping machine factory from China. As a spandex warping machine supplier, our spandex warping machine products have a stable system support to ensure their performance. With on-time online technical support and an easy operating system, most of our customers find it easy to run our machines and feel satisfied with our machine quality.

warping machine is equipment used for beam warping. With years of experience and ongoing technology development, A-ZEN spandex warping machine has become a fair smart one with many advantages combined, such as easier operation system, an intelligent camera detector, auto-saved data,a durable PLC system, strong reed needles, and highly-quality measuring speed rollers.

Main Features

The whole machine adopts asynchronous servo control. The tension is precisely controlled by the computer, which greatly reduces energy consumption.

The double-group tension roller adopts a double pneumatic control structure. This kind of structure has many advantages. Like precise control, separate structure design, convenient installation, and machine stability.

The surface of the tension roller is treated with a special material, which is more durable with a long lifespan. Meanwhile, this high-quality tension roller increases the friction to ensure the yarn’s smooth running.

The tension of the mother yarn can be automatically repaired and adjusted by the computer according to the warping data, which ensures the consistency of the bobbin tension from large to small during work.

The power failure stop function adopts a large-capacity battery, which can effectively ensure the normal shutdown of the equipment when the equipment is suddenly powered off.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Bosanski

Български

ქართული

Lietuvių

Wikang Tagalog

Servo Motor System

Servo Motor System