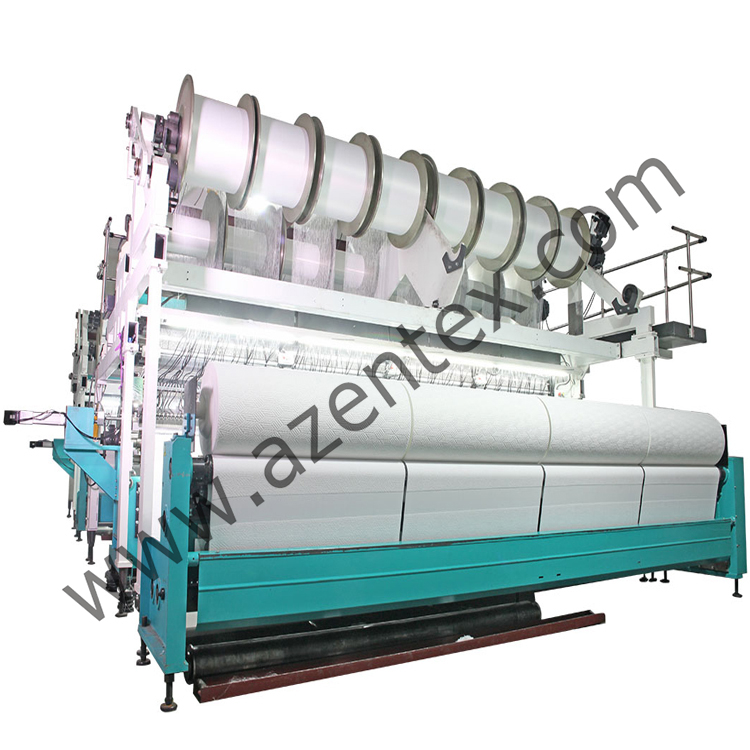

A-ZEN TS4-TJ terry towel machine is a professional warp knitting machine for the patterned microfiber terry towel textiles. The application of TS4-TJ towel textiles including cleaning terry towel, bath robes, beach towels, hotel towels, and others.

Compared with the traditional loom terry machines, warp knitting terry machine has a much higher productivity, and the process is more environmental friendly and resource-efficient.

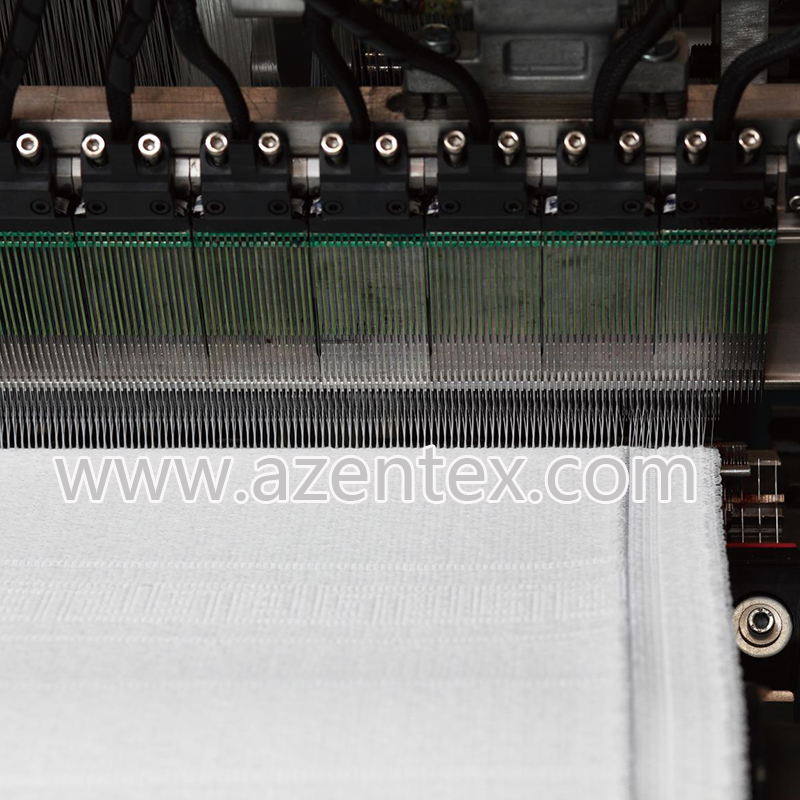

TS4-TJ is jacquard-patterned terry towel machine, with the piezo-jacquard system applied, TS4-TJ has a strong flexible design ability.

Now A-ZEN provides local installation and technical service for terry towel warp knitting machines in Turkey, Pakistan, and India.

Machine Features:

1. Stable Working Performance;

2. Reliable Spare-parts Partners

(1) Needle Elements Suppliers: Groz-Beckert, Saxonia;

(2) EL Drives Suppliers: Mitsubishi, Nidec, Yaskawa;

(3) Bearing Suppliers: NSK, INA, FAG;

(4) Needle Beds and Bars Material: Magnalium Material;

(5) Electrical Elements Suppliers: Schneider, Siemens, Omron, INVT;

(6) Take-up Belt: Bobotex.

3. Overseas Service Team:

Türkiye, India, Egypt, Indonesia, and Iran.

![jacquard pattern microfiber terry towel with jacquard pattern microfiber terry towel with]()

Patterned Terry Towel

![beach towel clean towel beach towel clean towel]()

Hotel Towel

![microfiber terry towel with jacquard pattern microfiber terry towel with jacquard pattern]()

Beach Towel

![warp knitted microfiber terry warp knitted microfiber terry]()

Patterned Terry Towel

Technical Details of TS4-TJ Jacquard Terry Machine

Technical Specifications

1. Working Width/Gauge: 186", 218"/E24;

2. Working Speed: 50-1400rpm (Depends on Yarn and Designs);

3. Bars/Knitting Elements: Individual Needle Bar with Compound Needles, Tongue Needles, 4 Guide Bars. All Bars and Beds are Made of Carbon-fiber-reinforced Material;

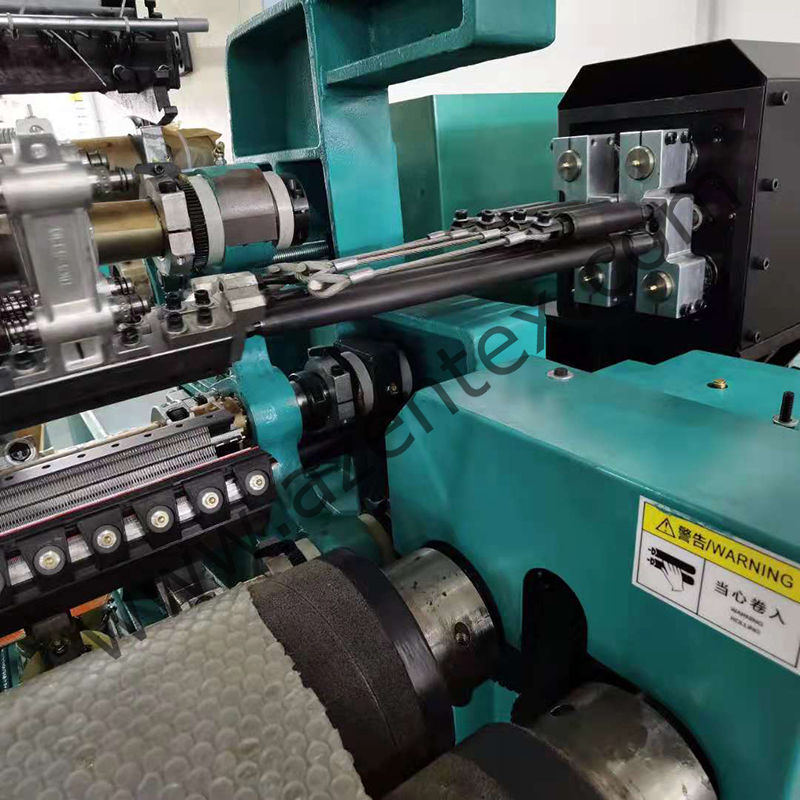

4. Pattern Drive System: EL Drive;

5. Yarn Let-off Device: EBC Yarn Let-off System;

6. Fabric Take-up: Electronical Fabric Take-up System;

7. Batching Device: Electronical Batching Device;

8. Laser Stop Detector and Online Service Program Equipped;

9. Air Blower Device: Equipped;

10. Individual Brushing Batching Device;

11. Piezo-Jacquard System: Saxonia Needle Pins.

Innovations & Advantages

Ensures consistent output for 3D mesh textiles with reliable operation.

Sourced from top suppliers: Needle Elements (Groz-Beckert, Saxonia), EL Drives (Mitsubishi, Nidec, Yaskawa), Bearings (NSK, INA, FAG), Needle Beds and Bars (Magnalium Material), Electrical Elements (Schneider, Siemens, Omron, INVT), Take-up Belt (Bobotex).

The EBC yarn let-off system reduces energy consumption by up to 15%.

Mitsubishi EL drives ensure accurate 3D mesh patterns for diverse applications.

Magnalium needle beds and NSK bearings enhance machine longevity.

![jacquard warp knitting terry towel machine jacquard warp knitting terry towel machine]()

Carbon-fiber guide bars

![Warp-knitted terry machine Warp-knitted terry machine]()

EL Drive System

![warp knitting terry machine warp knitting terry machine]()

Piezo-Jacquard Patterns

![microfiber terry towel with jacquard pattern microfiber terry towel with jacquard pattern]()

TS4-TJ patterned terry samples

![beach towel clean towel beach towel clean towel]()

TS4-TJ patterned terry samples

![A-ZEN textile A-ZEN textile]()

TS4-TJ patterned terry samples

FAQs About TS4-TJ Jacquard Terry Machine

Q:Are you a trading company or a manufacturer?

A-ZEN is a manufacturer since 2012, with a dedicated trading company established in 2017 under the A-ZEN brand, specializing in importing and exporting services.

Q:Do you offer local service?

We provide local service in India, Türkiye, Egypt, Indonesia, Pakistan, and Iran, with plans to expand further. Additionally, we offer detailed operation manuals and online technical support for efficient machine adjustments.

Q: How do you provide service if Chinese engineers can not come installation

A: Before machine delivery, we have a in-house test process, to make sure machine performance perfectly. After machine arrives, we provide in-time online guide to support our customer finish machine installation.

Q: How do you ensure your machine quality?

A: Firstly, we produce and provide lots of machines to the market, and our machines' lifespan and quality ensured by different markets over the years.

Secondly, we largely use renowned and market-tested spare-part brands, to make sure the mechnical and electrical part are durable.

Besides, we have reqularl service to customers, to check our machines quality and remind customers of maintenance, so our customers could run machine always in a stable performance.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Bosanski

Български

ქართული

Lietuvių

Wikang Tagalog