Are you a trading company or a manufacturer?

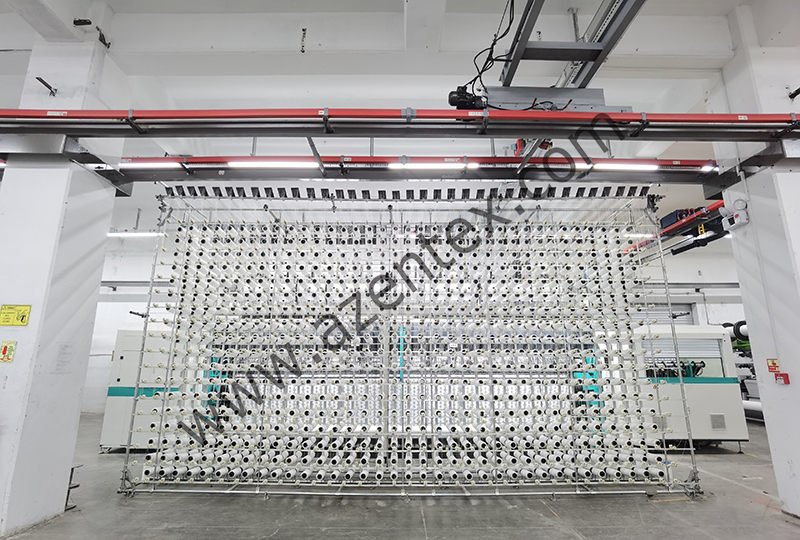

A-ZEN is a manufacturer since 2012, with a dedicated trading company established in 2017 under the A-ZEN brand, specializing in importing and exporting services.

Do you offer local service?

We provide local service in India, Türkiye, Egypt, Indonesia, Pakistan, and Iran, with plans to expand further. Additionally, we offer detailed operation manuals and online technical support for efficient machine adjustments.

How do you provide service if Chinese engineers cannot come for installation?

Before delivery, we conduct an in-house test to ensure perfect machine performance. After arrival, we provide timely online guidance to support customers in completing machine installation.

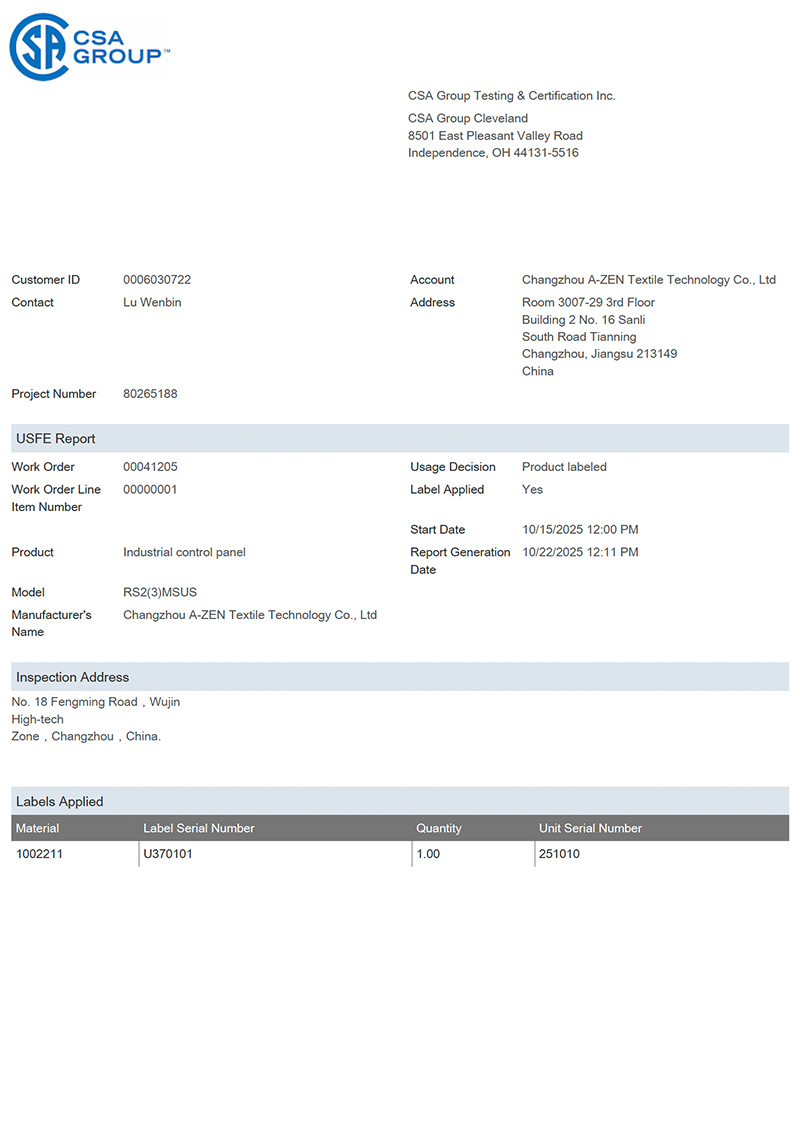

How do you ensure the quality of the MJF machine?

Proven lifespan and quality through extensive market use.

Incorporates renowned, market-tested spare parts from brands like Groz-Beckert, Mitsubishi, and NSK.

Regular customer service to monitor machine quality and provide maintenance reminders.

Each machine undergoes rigorous testing before delivery.

What types of yarn are compatible with the MJF machine?

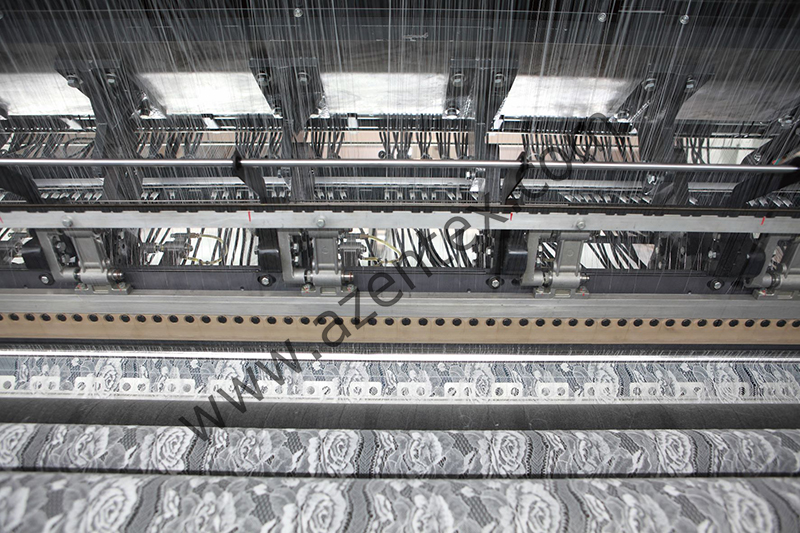

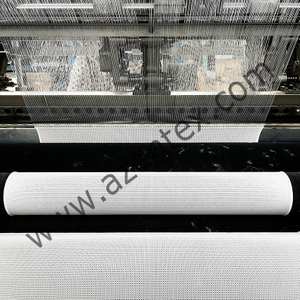

The MJF supports a wide range of yarns, including polyester, nylon, and spandex, ensuring versatility for intricate lace fabric production.

How to maintain the MJF lace machine?

Regular maintenance includes cleaning needle beds, checking EL drives, and following our detailed operation manual. A-ZEN’s service teams offer ongoing support.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Bosanski

Български

ქართული

Lietuvių

Wikang Tagalog