![jacquard yarn jacquard yarn]()

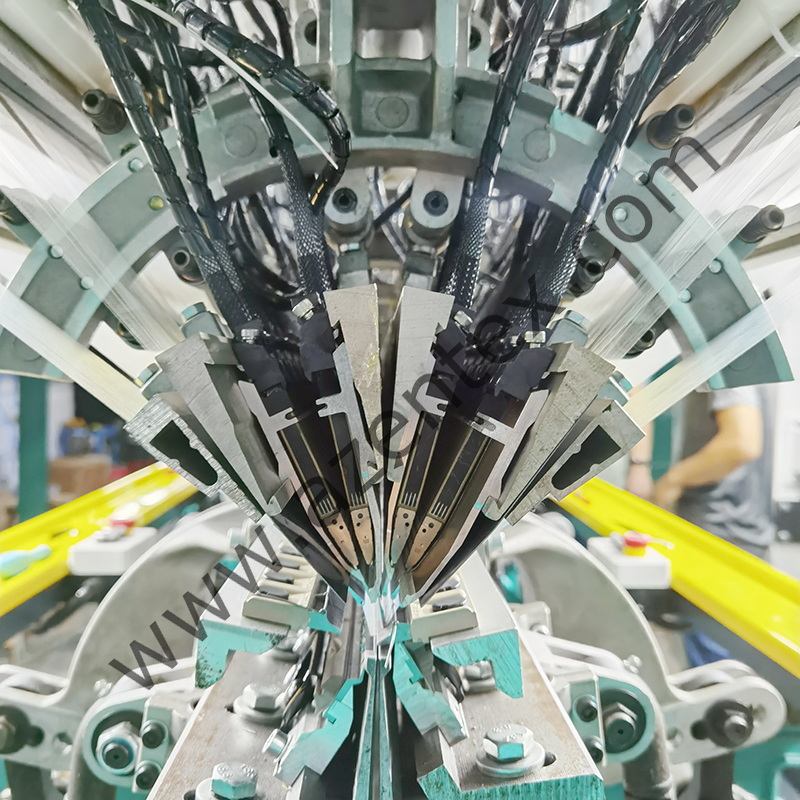

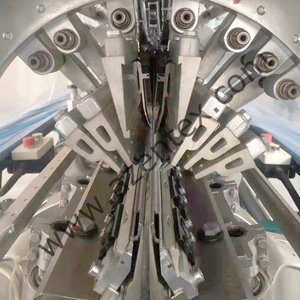

Raschel Double Needle Bar Jacquard Warp Knitting Machine with double jacquard RDJ4/2 (RDJ6/2) is designed to produce warp-knitted seamless fabrics, which are used as seamless pantyhose, seamless leggings, elastic sportswear, yoga clothes, female stockings, wedding gloves, jacquard trim ribbon or ribbon trims, and other fashionable outerwear.

The advantage of warp-knitted seamless fabrics is that it is produced in a single sequence without any seam process after the knitting work.

Besides, the high productivity and shape flexibility outweigh other knitting machines.

Lastly, thanks to the piezo-jacquard technology, various patterns are available on the RDJ4/2 machine.

To those who produce seamless fabrics from the circular knitting machine, RDJ4/2 shows its strong merit in the effective rate of finished fabrics, because the yarn does not run if it breaks off, and the fabric will bring a comfortable skin feeling to its user.

Nowadays, the piezo-jacquard technology is used on other double-needle bar machine models, such as RDJ5/1, RDJ6/1, RDJ7/1, and RDJ6/2.

Machine Features:

1. Stable Working Performance;

2. Reliable Spare-parts Partners

(1) Needle Elements Suppliers: Groz-Beckert, Saxonia;

(2) EL Drives Suppliers: Mitsubishi, Nidec, Yaskawa;

(3) Bearing Suppliers: NSK, INA, FAG;

(4) Needle Beds and Bars Material: Magnalium Material;

(5) Electrical Elements Suppliers: Schneider, Siemens, Omron, INVT;

(6) Take-up Belt: Bobotex.

3. Overseas Service Team:

Türkiye, India, Egypt, Indonesia, and Iran.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Bosanski

Български

ქართული

Lietuvių

Wikang Tagalog