Overview of A-ZEN AZ2885 Flannel Blanket Warp Knitting Machine

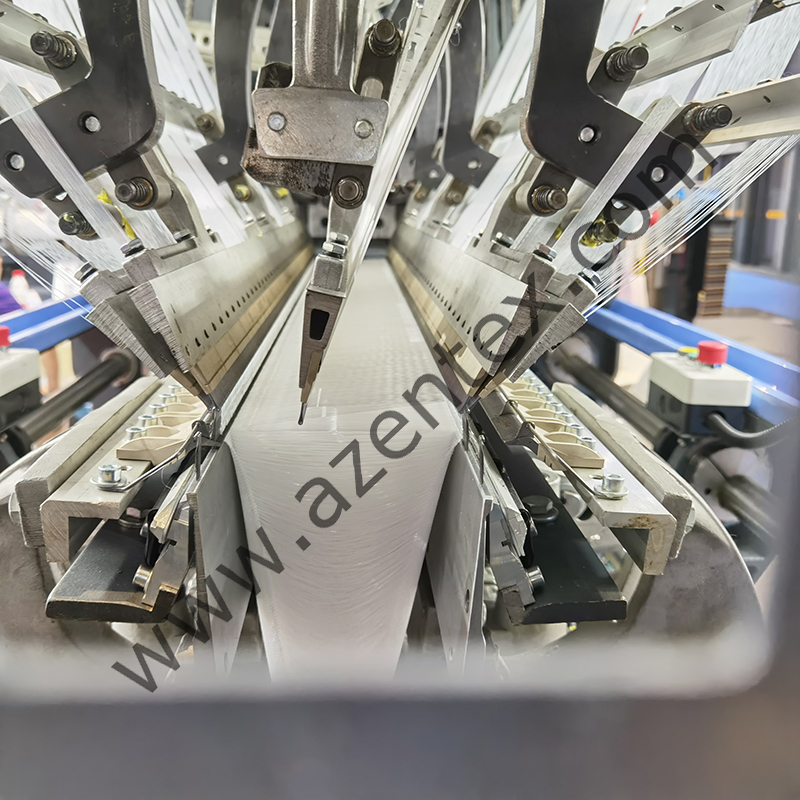

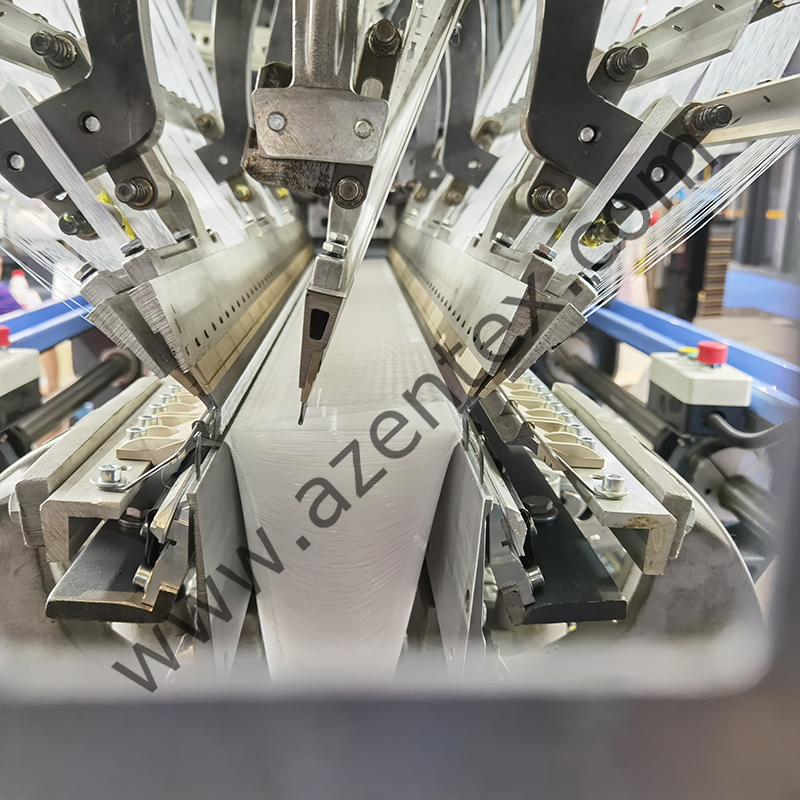

Raschel flannel blanket and super-large distance warp knitting machine refers to a double-needle bar raschel machine that has a wide knock-over comb distance from 8-50mm. This kind of double-needle bar warp knitting machine![raschel blanket raschel blanket]() produces flannel fabrics, blanket fabrics, mink blankets, microfiber coral fleece fabric, microfiber cleaning rags, velvet carpets, fleece plush, large-distance warp-knitted air-mesh spacer and rabbit fur coats.

produces flannel fabrics, blanket fabrics, mink blankets, microfiber coral fleece fabric, microfiber cleaning rags, velvet carpets, fleece plush, large-distance warp-knitted air-mesh spacer and rabbit fur coats.

A-ZEN textile has started producing the double-needle bar warp knitting machine for more than 10 years. Our double-needle bar machines AZ2885, (H)RD5, and RD6 all belong to the raschel flannel blanket warp knitting machines.

With technology and accessory parts quality improving, our double-needle bar warp knitting machine quality is more stable, and running speed is much higher in the market. Now the widest raschel doube-needle bar warp knitting machine width reaches 210".

A heating blanket (conductive yarn knitted in) is the most favorite gift in cold winter. As a must-have, this special heating blanket is produced from the warp knitting machine AZ2885 model, it is moisture-absorbing, heating, and stylish.

By using GB3 in EL drive, the AZ2885 is an ideal machine for producing zig-zag microfiber cleaning rags or cloths. The cleaning towels produced by AZ2885 have prominent advantages as wahsable fast drying, super absorbent, reusable and multifunctional towels.

Machine Features:

1. Stable Working Performance;

2. Reliable Spare-parts Partners

(1) Needle Elements Suppliers: Groz-Beckert, Saxonia;

(2) EL Drives Suppliers: Mitsubishi, Nidec, Yaskawa;

(3) Bearing Suppliers: NSK, INA, FAG;

(4) Needle Beds and Bars Material: Magnalium Material;

(5) Electrical Elements Suppliers: Schneider, Siemens, Omron, INVT;

(6) Take-up Belt: Bobotex.

3. Overseas Service Team:

Türkiye, India, Egypt, Indonesia, and Iran.

PDF Documentation for AZ2885 Flannel Blanket Machine

Technical Details of AZ2885 Flannel Blanket Machine

Technical Specifications

| 1 | Working Width | 90", 100", 186", 200" |

| 2 | Machine Gauge | E18, E22 |

| 3 | Working Speed | 50-850 RPM (Depends on Yarn and Designs) |

| 4 | Knock-over Comb Bar Distance | 8-24mm, 30-50mm, 50-150mm |

| 5 | Bars/Knitting Elements | 2 needle bars with latch needle units (individual needle and needle block optional), 2 knock-over comb bars, 5 or 6 ground bars |

| 6 | Pattern Drive System | Pattern Discs Drive or EL Drive (Optional) |

| 7 | Yarn Let-off Device | EBC Yarn Let-off System |

| 8 | Fabric Take-up | Electronic Fabric Take-up System |

| 9 | Batching Device | Electronic Batching Device |

| 10 | Laser Stop Detector and Online Service Program | Equipped |

| 11 | Air Blower Device | Optional |

![Original Machine Design & Custom Development1 Original Machine Design & Custom Development1]()

Innovations & Advantages

Ensures consistent output for 3D mesh textiles with reliable operation.

Sourced from top suppliers: Needle Elements (Groz-Beckert, Saxonia), EL Drives (Mitsubishi, Nidec, Yaskawa), Bearings (NSK, INA, FAG), Needle Beds and Bars (Magnalium Material), Electrical Elements (Schneider, Siemens, Omron, INVT), Take-up Belt (Bobotex).

The EBC yarn let-off system reduces energy consumption by up to 15%.

Mitsubishi EL drives ensure accurate 3D mesh patterns for diverse applications.

Magnalium needle beds and NSK bearings enhance machine longevity.

![rabbit fur warp knitting machine rabbit fur warp knitting machine]()

Rabbit Fur Warp Knitting Machine

![RD6 Latch Needles RD6 Latch Needles]()

Latch Needles

![Air-mesh-mattress Air-mesh-mattress]()

3D Bed Mattress Spacer

![raschel-blanket-fleece raschel-blanket-fleece]()

Rabbit fur plush (Pile height above 20mm)

![rabbit-fur-coat rabbit-fur-coat]()

Rabbit Fur Coat

![kitchen-towels kitchen-towels]()

Microfiber Kitchen Towels

![luminous-flannel-fabrics luminous-flannel-fabrics]()

Luminous blanket, soft plush space blanket glow in the dark luminous astronaut blanket for kids. Developed in 2016 on A-ZEN AZ2885 machines.

Applications of AZ2885 Flannel Blanket Fabrics

![microfiber-color-towel-blanket microfiber-color-towel-blanket]()

Microfiber Blanket

![fleece-blankets fleece-blankets]()

Fleece Blanket

![]()

Microfiber Cleaning Rag

![]()

Microfiber Cleaning Rag

Advantages of A-ZEN Service

Original Machine Design & Custom Development

A-ZEN offers tailored machine designs and custom development solutions to meet specific client needs, ensuring optimal performance for diverse textile applications.

![Original-Machine-Design Original-Machine-Design]()

Original Machine Design & Custom Development

![Custom-Development Custom-Development]()

Original Machine Design & Custom Development

ISO-Standard Assembly and Quality Inspection

![Quality-Control-During-Assembly Quality-Control-During-Assembly]()

Quality Control During Assembly

![Quality-Control-During-Assembly-2 Quality-Control-During-Assembly-2]()

Quality Control During Assembly

![Quality-Control-During-Assembly-3 Quality-Control-During-Assembly-3]()

Quality Control During Assembly

![Quality-Control-During-Assembly-4 Quality-Control-During-Assembly-4]()

Quality Control During Assembly

Professional Packing and Shipping Team

![Warp-Knitting-Machine-Delivery Warp-Knitting-Machine-Delivery]()

Warp Knitting Machine Delivery

![Seaworthy-Package Seaworthy-Package]()

Seaworthy Package

![Professional-Shipping-1 Professional-Shipping-1]()

Professional Shipping

![Professional Shipping Professional Shipping]()

Professional Shipping

Expert After-Sales and Global Service Network

A-ZEN provides local service in India, Türkiye, Egypt, Indonesia, Pakistan, and Iran, with plans to expand further. Our global service teams ensure timely support and maintenance.

Sustainable Textile Production with AZ2885 Double Needle Bar Machine

The AZ2885’s energy-efficient design reduces power consumption by up to 15%, and its compatibility with eco-friendly yarns supports sustainable textile manufacturing, meeting modern environmental standards.

![Sustainable textile production with AZ2885]()

Sustainable Production

FAQs About AZ2885 Double Needle Bar Machine

What is the knock-over comb distance of the AZ2885 machine?

The AZ2885 double needle bar raschel warp knitting machine has a knock-over comb distance ranging from 8mm to 150mm.

What is the popular gauge for the AZ2885 machine?

Most customers choose gauges E18 and E22 for the AZ2885.

How do you ensure the quality of the AZ2885 machine?

Proven lifespan and quality through extensive market use.

Incorporates renowned, market-tested spare parts from brands like Groz-Beckert, Mitsubishi, and NSK.

Regular customer service to monitor machine quality and provide maintenance reminders.

Each machine undergoes rigorous testing before delivery.

What types of yarn are compatible with AZ2885?

The AZ2885 supports a wide range of yarns, including polyester, microfiber, and conductive yarns, ensuring versatility for flannel blanket production.

How to maintain the AZ2885 warp knitting machine?

Regular maintenance includes cleaning needle beds, checking EL drives, and following our detailed operation manual. A-ZEN’s service teams offer ongoing support.

Do you offer local service?

We provide local service in India, Türkiye, Egypt, Indonesia, Pakistan, and Iran, with plans to expand further. Additionally, we offer detailed operation manuals and online technical support for efficient machine adjustments.

Company Information

![warping knitting machine manufacture warping knitting machine manufacture]()

Manufacturing Factories:

We have four workshops, two of them are warp knitting machines and warping machines workshops, and another two are fabric production mill and spare parts manufacture workshops separately. New machines are thoroughly tested in our fabric knitting factory before market release. Spare parts, including compound needle beds, tongue needle beds, needle guide bars, sinker beds, and latch needle beds, are produced using CNC machines, compatible with both Chinese and German warp knitting machines.

![exhibition booth exhibition booth]()

Global Exhibition:

We participate in global textile machinery exhibitions such as ITMA, ITM, and ITME, showcasing our latest technology and cost-effective products. These events allow us to gather client feedback and refine our machines to meet market demands.

![Customer-Training Customer-Training]()

Customer Training:

Technical support is a cornerstone of our services. We provide comprehensive training through professional manuals, online guides, video tutorials, and on-site training in over 10 countries, including Turkey, India, Pakistan, Indonesia, Iran, and Egypt. Our timely and professional support has earned a strong reputation globally.

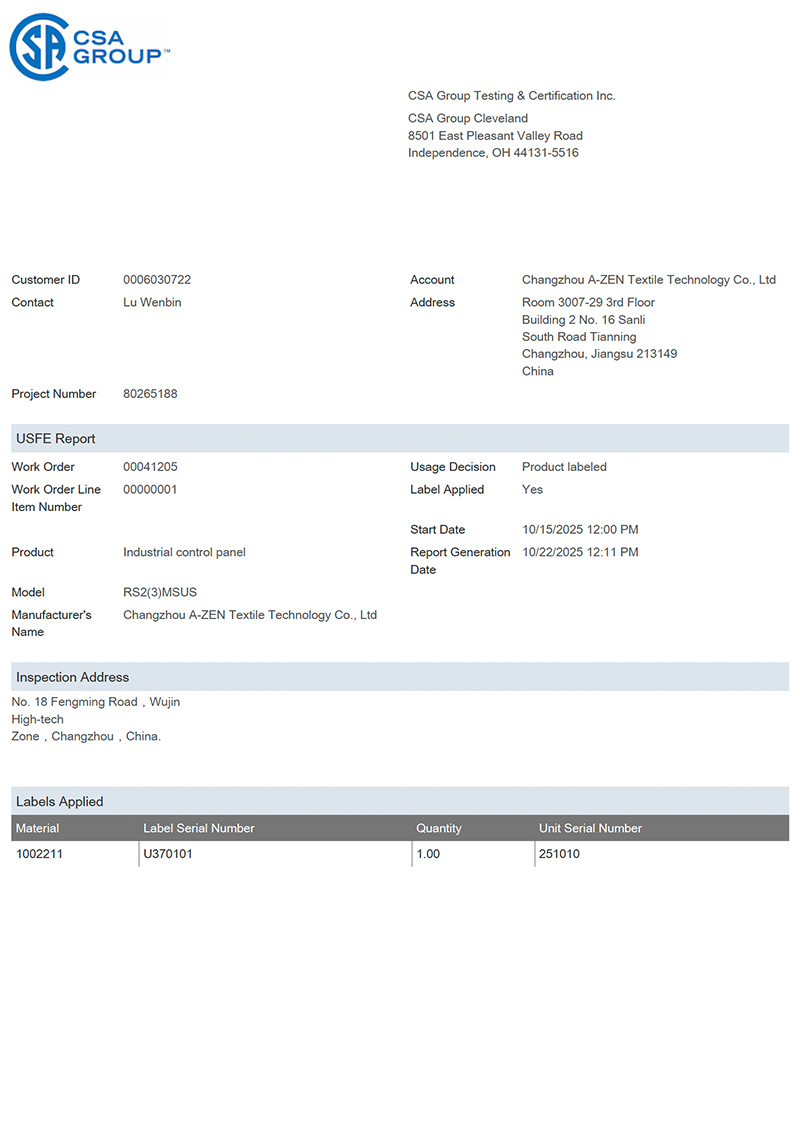

Certificates

![CE1 CE1]()

Certificate

![CE2 CE2]()

Certificate

![CE3 CE3]()

A-ZEN Trademark

![patent3 patent3]()

Patent

![patent2 patent2]()

Patent

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Bosanski

Български

ქართული

Lietuvių

Wikang Tagalog