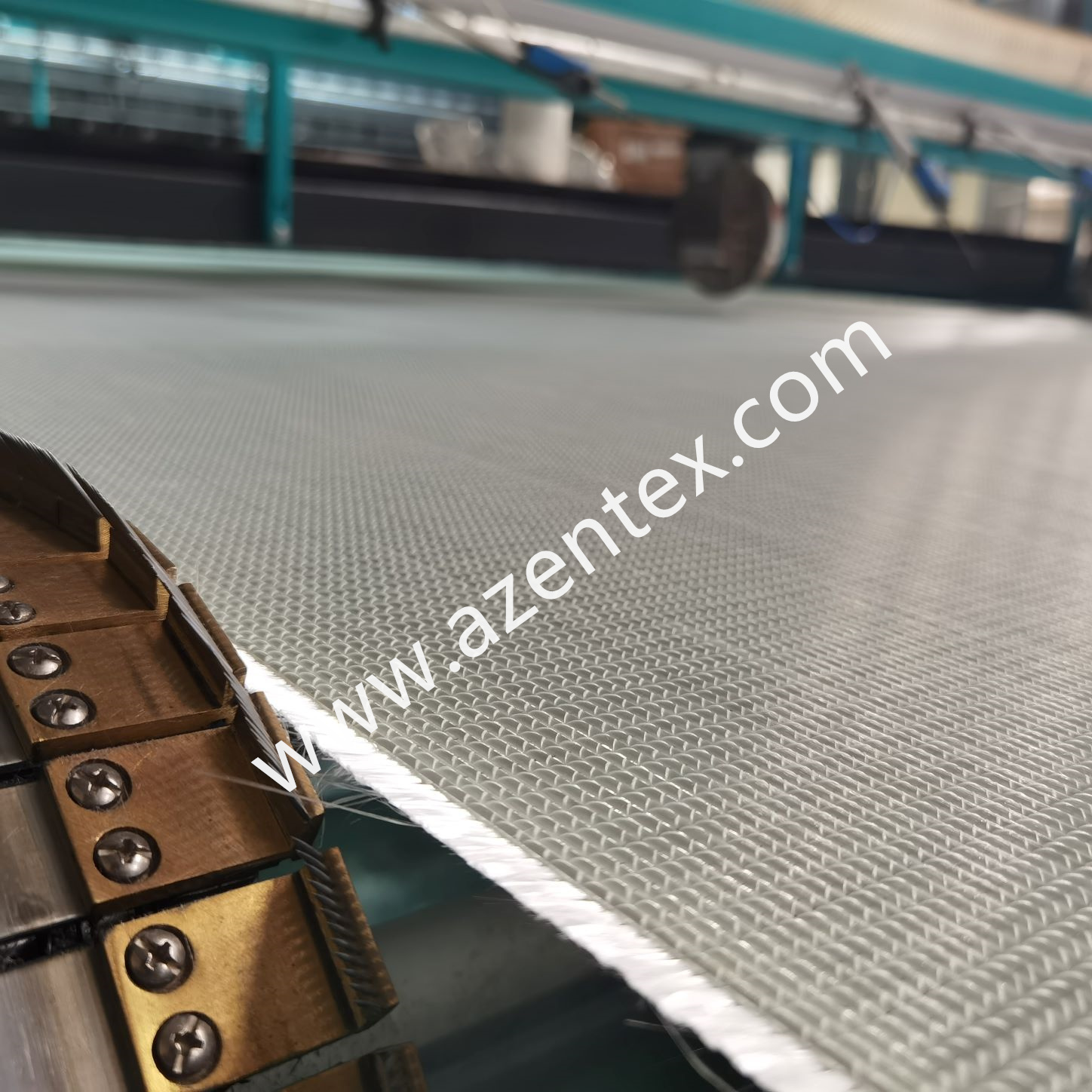

Raschel weft-insertion warp knitting machine RS2(3)MSUS refers to the high-speed Raschel machine with the weft-insertion carrier, which makes an in-lay structure by carrying parallel yarns that move horizontally.

Raschel biaxial fabrics could use fiberglass yarn or other heavy material, and the fabrics are widely used as geogrids, flex banners, hometextiles (warp-knitted weft-insertion curtain mesh), and industrial reinforced fiberglass mesh.

![AZEN Biaxial Machine AZEN Biaxial Machine]()

Biaxial industrial textile is also called Directionally Oriented Structure textile. This textile has strong stability and high strength, especially after the alkali-resistant latex coating process. Because of this prominent advantage, fiberglass mesh is widely used as interior and exterior wall mesh nowadays.

Compared with the traditional steel wall mesh, fiberglass mesh is resistant to corrosion, longer lifespan, and is much more economical. What's more, fiberglass mesh, as a new alternative wall mesh material, is more environmentally friendly.

We adopt quality warp knitting parts on our warp knitting machines to ensure a stable working performance of our machine, such as Groz-Beckert, Saxonia needles, Carbon-fiber material, European electronic elements, and other market-tested parts.

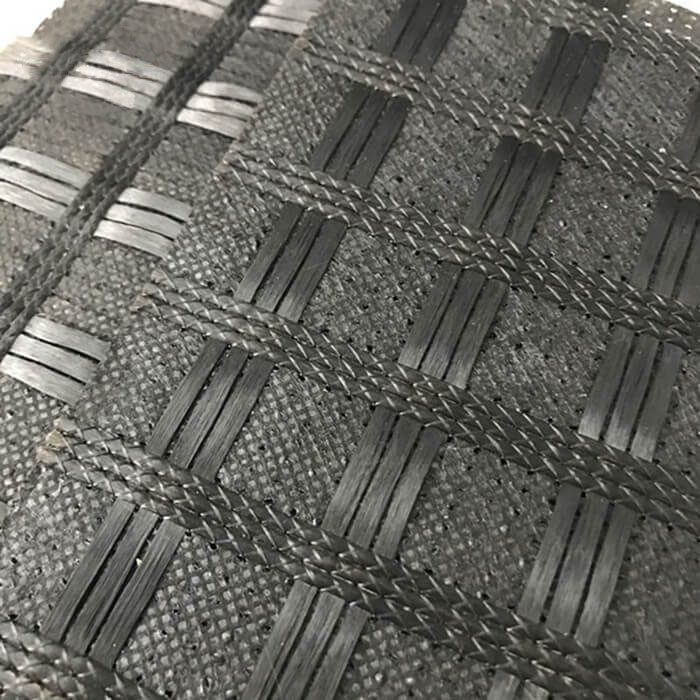

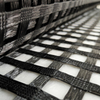

Biaxial warp-knitted textile is widely used as fiberglass composite geotextile, reinforced wind energy blades, building wall mesh, ski board, signage board or outer advertising flex banner, yacht, and many other composite textiles. Biaxial warp-knitted industrial textile is the most promising textile for the future.

![Fiberglass-Geogrids Fiberglass-Geogrids]()

Fiberglass Geogrids

![Flex-Banner Flex-Banner]()

Flex Banners

![Wind-Energy-Blades Wind-Energy-Blades]()

Wind Energy Blades

![Ski-Boards Ski-Boards]()

Ski Boards

FAQs About RS2(3)MSUS Weft Insertion Machine

Q: You are a trading company or a manufacturer

A: We have been a manufacturer since 2012, and we established our own trading company in 2017, the brand of which is A-ZEN, which specializes in importing and exporting services.

Q: Do you offer local service?

A: We provide local service in India, Turkey, Egypt, Indonesia, Pakistan, and Iran so far, and we will enlarge our service teams in more countries in the near future.

Q: How do you provide service if Chinese engineers can not come installation

A: Before machine delivery, we have an in-house test process to make sure the machine performs perfectly. After the machine arrives, we provide an in-time online guide to support our customers in finishing machine installation.

Q: How do you ensure your machine quality

A: Firstly, we produce and provide lots of machines to the market, and our machines' lifespan and quality have been ensured by different markets over the years.

Secondly, we largely use renowned and market-tested spare-part brands, to make sure the mechnical and electrical parts are durable.

Besides, we have regular service to customers, to check the quality of our machines and remind customers of maintenance, so our customers can always run the machine in stable performance.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Bosanski

Български

ქართული

Lietuvių

Wikang Tagalog

RS2(3)MSUS Weft Insertion Machine Catalogue

RS2(3)MSUS Weft Insertion Machine Catalogue