A-ZEN offers 2-bar, 3-bar, and 4-bar high-speed tricot machines, which are designed for producing elastic and non-elastic warp-knitted textiles.

Tricot machines are equipped with compound needles, also known as bearded needles.

The sinker needles used in the tricot warp knitting machine control the fabric throughout the knitting cycle. The throats of the sinker needles hold the fabric while the tongue needles rise to form new loops.

![yoga-wear-sports-wear yoga-wear-sports-wear]()

Thanks to the EL servo drive system, the zig-zag patterns become available on the high-speed tricot warp knitting machines.

With more advanced functions applied, the tricot warp knitting machines are more durable and efficient.

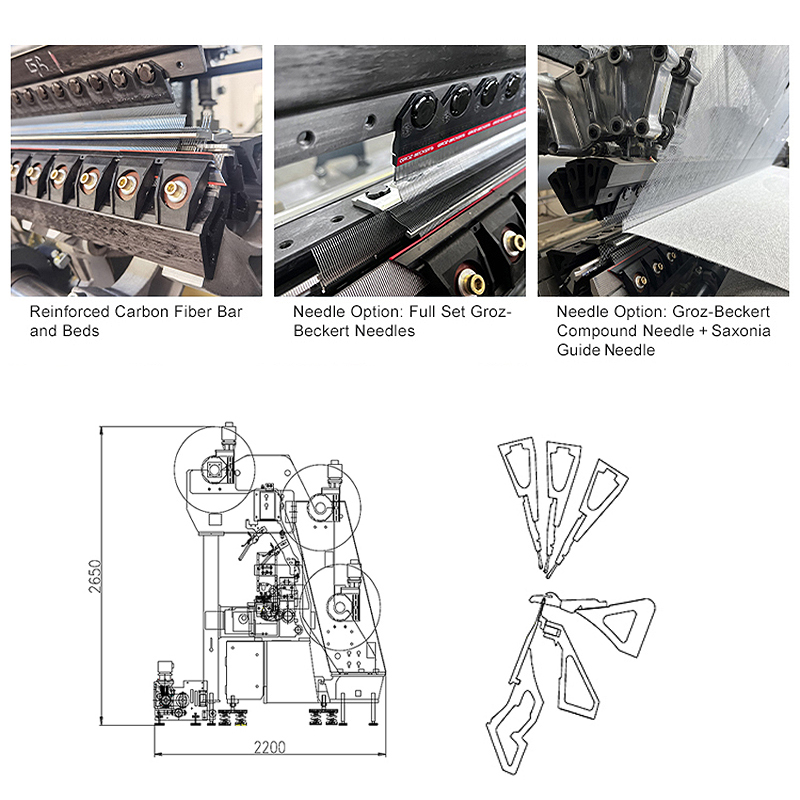

The working speed of HTS3M could reach 2,200 rpm, full bars and needle beds are made from high-strength carbon fiber material, and more flexible working widths are available: 186", 218", 250", 290", 330", and 360".

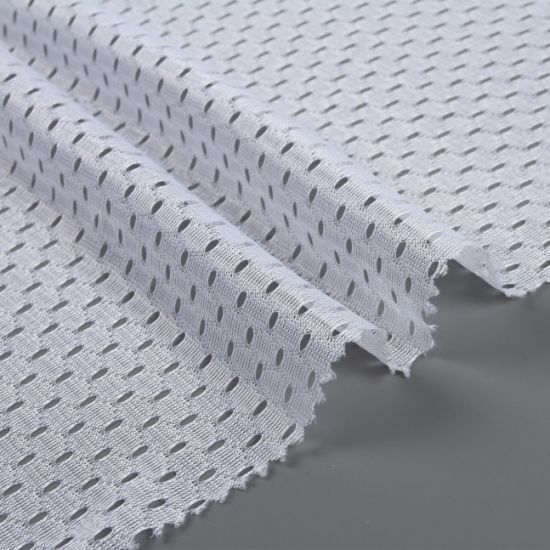

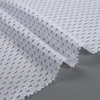

Tricot Machine HTS3M Fabrics Applications:

HTS3M tricot machines mainly produce automotive interior textiles, sportswear, yoga wear, upholstery velvet fabrics, mesh nets, curtains, plush toys, and many other textiles.

![tricot-holland-velvet tricot-holland-velvet]()

Holland Velvet

![automotive tricot textile automotive tricot textile]()

Automotive Fabrics

![Velvet Velvet]() Upholstery Velvet

Upholstery Velvet

Technical Details of HKS3M Tricot Machine

Technical Specifications

| 1. Working Width/Gauge | 186", 218", 250", 290", 330", 360"/E28, E32, E36; |

| 2. Working Speed | 50–2,200 rpm (Depends on Yarn and Designs); |

| 3. Bars/Knitting Elements | Individual Needle Bar with Compound Needles, Tongue Needles, and 3 Guide Bars.

All Bars and Beds are Made of Carbon-fiber-reinforced Material. |

| 4. Pattern Drive System | Pattern Discs Drive or EL Drive (Optional); |

| 5. Yarn Let-off Device | EBC Yarn Let-off System; |

| 6. Fabric Take-up | Electrical Fabric Take-up System; |

| 7. Batching Device | Electrical Batching Device; |

| 8. Laser Stop Detector, and Air-blower Device | Equipped. |

| 9. Heating & Fan Device | Equipped. |

| 10. Camera Detector | Optional. |

Innovations & Advantages

![Liquid Nitrogen Liquid Nitrogen]()

1. Liquid Nitrogen Cryogenic Fitting

Description: The ultra-cold assembly process using liquid nitrogen at -196°C shrinks the bearing inner ring by 0.15–0.25mm, achieving an interference fit without damaging the bearing’s internal structure.

Advantage: Prevents micro-deformation from thermal stress, maintaining ≤0.3μm preload loss over 10-year operation.

![Thermostatic Needle Assembly Thermostatic Needle Assembly]()

2. Thermostatic Needle Assembly

Description: Assemble needle parts in a constant temperature workshop at 25±1℃.

Advantages: Eliminates thermal expansion/contraction errors, improves operating efficiency, and reduces fabric defects.

![7075-T6 Aluminum Drive Components-1 7075-T6 Aluminum Drive Components-1]()

3. 7075-T6 Aluminum Drive Components

Description: Drive parts made of 7075-T6 aluminum (572MPa UTS) with hard-coat anodization (50μm).

Advantages: Lighter yet stronger, ideal for high-speed warp knitting machines and longer machine life.

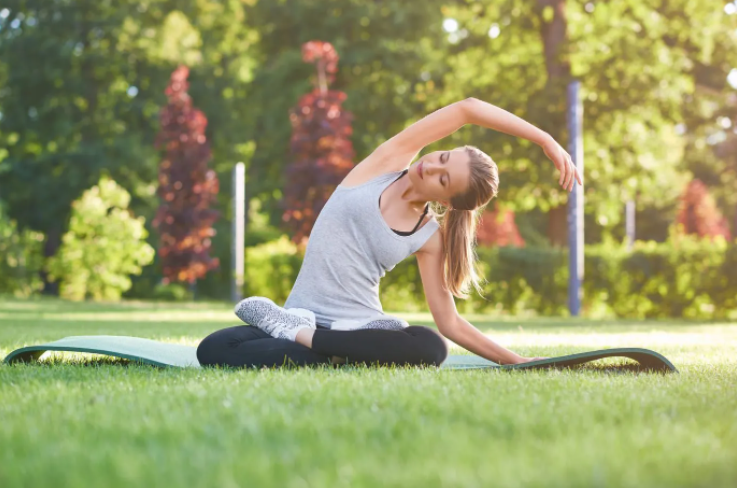

4. Full Inspection of Core Components

Description: Key components measured with a coordinate measuring machine (accuracy: 1.8 μm + L/350) to generate a 3D deviation map.

Advantages: Eliminates defective parts, reduces assembly errors, improves fit and performance.

5. Thorough In-house Testing Before Delivery

AZEN Tricot Machine Spare Parts Quality

![]()

A-ZEN Tricot machines are equipped with top brands to ensure each machine's stability and lifespan

![]()

Reinforced carbon fiber bar and beds

Full set of original German Groz-Beckert needles

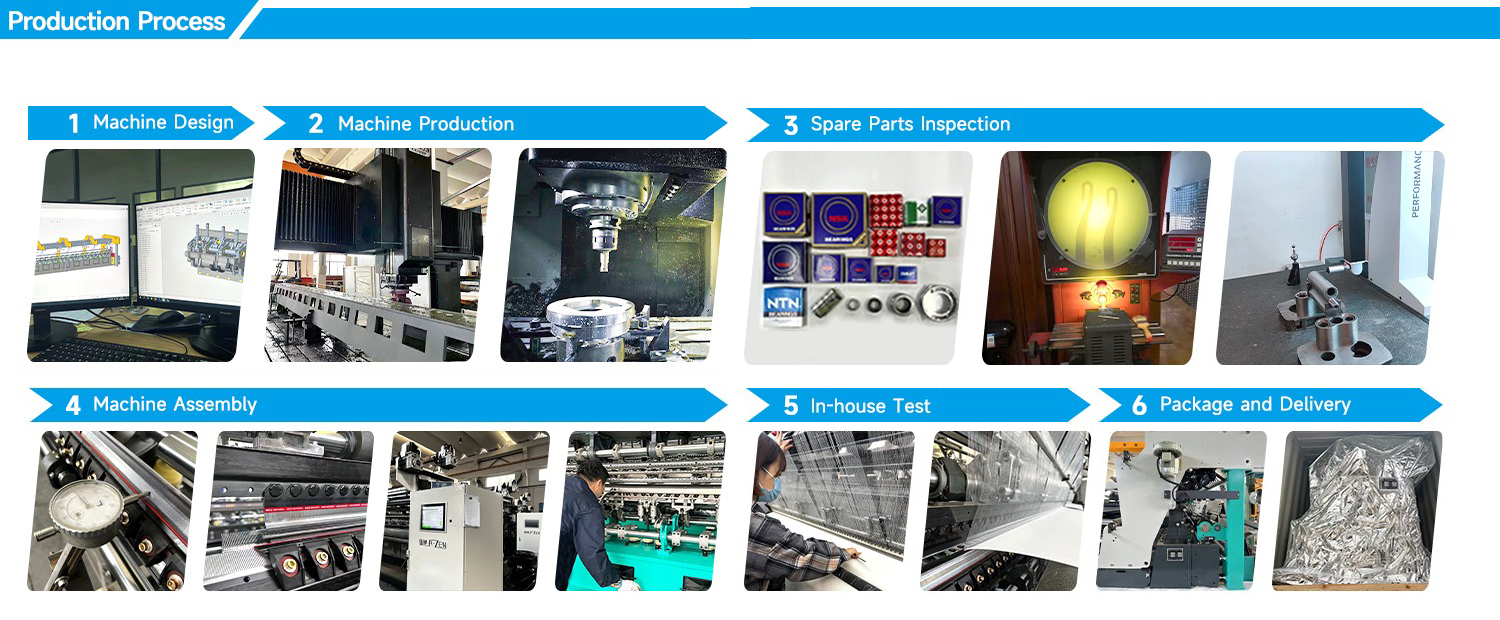

Tricot Machine HTS3M Factory Production Process

1. Design & Motion Check

Innovative machine design with full running action verification.

2. Precision Component Inspection

Quality checks from oil tank production to bearing assembly.

3. Premium Parts Selection

Only high-grade components for stable performance.

4. Strict Assembly Control

Each assembly step is carefully inspected for accuracy.

5. In-House Performance Testing

Comprehensive testing before delivery to ensure reliability.

6. Secure Export Packaging

Durable and safe packing for global shipment.

![production-process production-process]()

Video: HTS3M Producing Tricot Fabrics

Advantages of A-ZEN Service

Original Machine Design & Custom Development

A-ZEN offers tailored machine designs and custom development solutions to meet specific client needs, ensuring optimal performance for diverse textile applications.

![Original-Machine-Design Original-Machine-Design]()

Original Machine Design & Custom Development

![Custom-Development Custom-Development]()

Original Machine Design & Custom Development

ISO-Standard Assembly and Quality Inspection

![Quality-Control-During-Assembly Quality-Control-During-Assembly]()

Quality Control During Assembly

![Quality-Control-During-Assembly-2 Quality-Control-During-Assembly-2]()

Quality Control During Assembly

![Quality-Control-During-Assembly-3 Quality-Control-During-Assembly-3]()

Quality Control During Assembly

![Quality-Control-During-Assembly-4 Quality-Control-During-Assembly-4]()

Quality Control During Assembly

Professional Packing and Shipping Team

![Warp-Knitting-Machine-Delivery Warp-Knitting-Machine-Delivery]()

Warp Knitting Machine Delivery

![Seaworthy-Package Seaworthy-Package]()

Seaworthy Package

![Professional-Shipping-1 Professional-Shipping-1]()

Professional Shipping

![Professional Shipping Professional Shipping]()

Professional Shipping

Expert After-Sales and Global Service Network

A-ZEN provides local service in India, Türkiye, Egypt, Indonesia, Pakistan, and Iran, with plans to expand further. Our global service teams ensure timely support and maintenance.

HTS3M vs. Other Warp Knitting Machines

| Model | Working Width | Speed (RPM) | Applications |

| HTS2M | 186",218",260" | 50-2300 | Mosquito Net Mesh; Tulle Mesh |

| HTS3EL | 218",290",330" | 50-2200 | Mercerized Velvet; Automotive Fabrics; Outerwear

|

| HTS4EL | 218",250",290",330" | 50–2000 | Automotive interiors, sportswear, upholstery velvet, crinkle fabrics |

Sustainable Textile Production with HTS3M

The HKS3M’s energy-efficient EBC system reduces power consumption by up to 15%, and its compatibility with eco-friendly yarns supports sustainable textile manufacturing, meeting modern environmental standards.

![Sustainable textile production with HKS3M]()

Sustainable Production

FAQs About HKS3M Tricot Machine

Q: Did you produce the tricot machines by yourself?

A: A-ZEN textile is established as a trading company to serve customers with machines, spare parts, and yarn for the international markets. But we have had our own production plant for over 10 years. We are not simply an installation factory, since we have our own professional R&D team.

Q: How are your tricot warp knitting machines different from others?

From the technical team our technical team has been in this field for more than 20 years. They know machine structures, machine parts qualities, and machine skills very well.

We have our own CNC plant. For most machine parts, we have stable suppliers, but we will still do CNC work to reduce the size difference before machine installation to improve our machine stability and make them more durable.

For after-sales service, our sales and technical teams are always online for our customers. When they need our technical support, we always provide on-time service. Meanwhile, we have a local service team in some markets.

Company Information

![warping knitting machine manufacture warping knitting machine manufacture]()

Manufacturing Factories:

We have four workshops, two of which are warp knitting machines and warping machines workshops, and another two are fabric production mill and spare parts manufacture workshops. New machines are thoroughly tested in our fabric knitting factory before market release. Spare parts, including compound needle beds, tongue needle beds, needle guide bars, sinker beds, and latch needle beds, are produced using CNC machines, compatible with both Chinese and German warp knitting machines.

![exhibition booth exhibition booth]()

Global Exhibition:

We participate in global textile machinery exhibitions such as ITMA, ITM, and ITME, showcasing our latest technology and cost-effective products. These events allow us to gather client feedback and refine our machines to meet market demands.

![Customer-Training Customer-Training]()

Customer Training:

Technical support is a cornerstone of our services. We provide comprehensive training through professional manuals, online guides, video tutorials, and on-site training in over 10 countries, including Turkey, India, Pakistan, Indonesia, Iran, and Egypt. Our timely and professional support has earned a strong reputation globally.

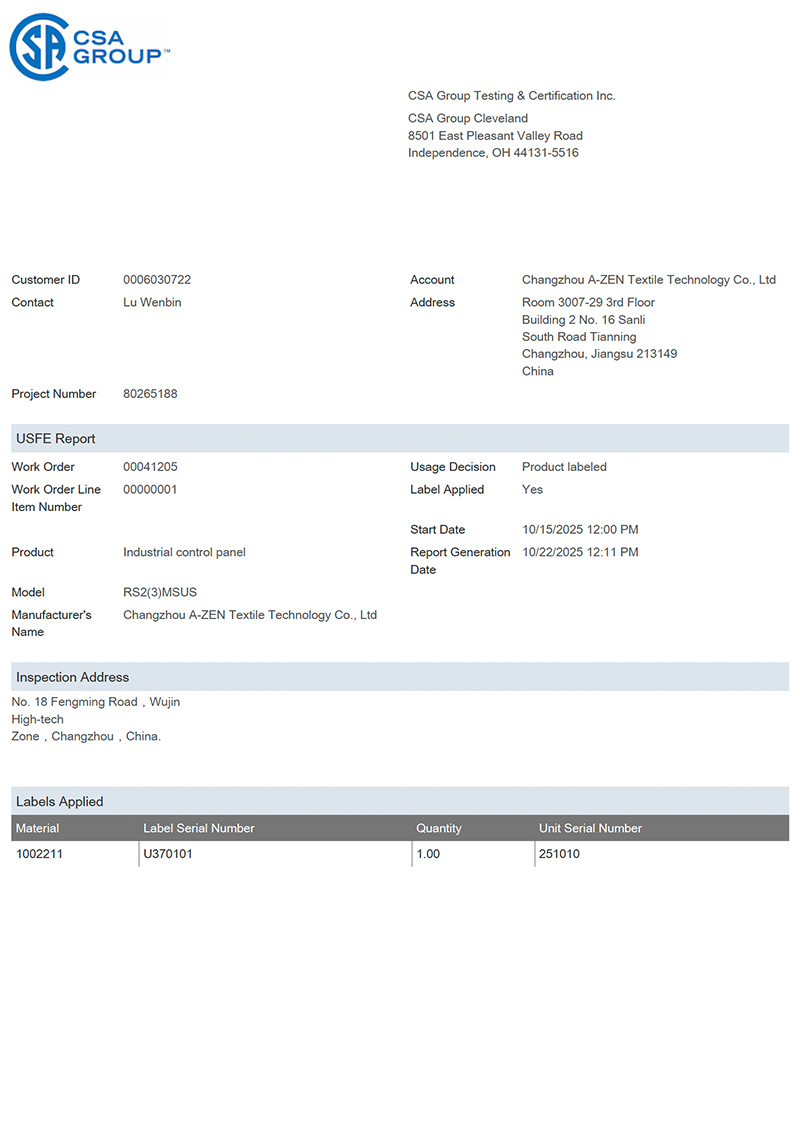

Certificates

![CE1 CE1]()

Certificate

![CE2 CE2]()

Certificate

![CE3 CE3]()

A-ZEN Trademark

![patent3 patent3]()

Patent

![patent2 patent2]()

Patent

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Bosanski

Български

ქართული

Lietuvių

Wikang Tagalog