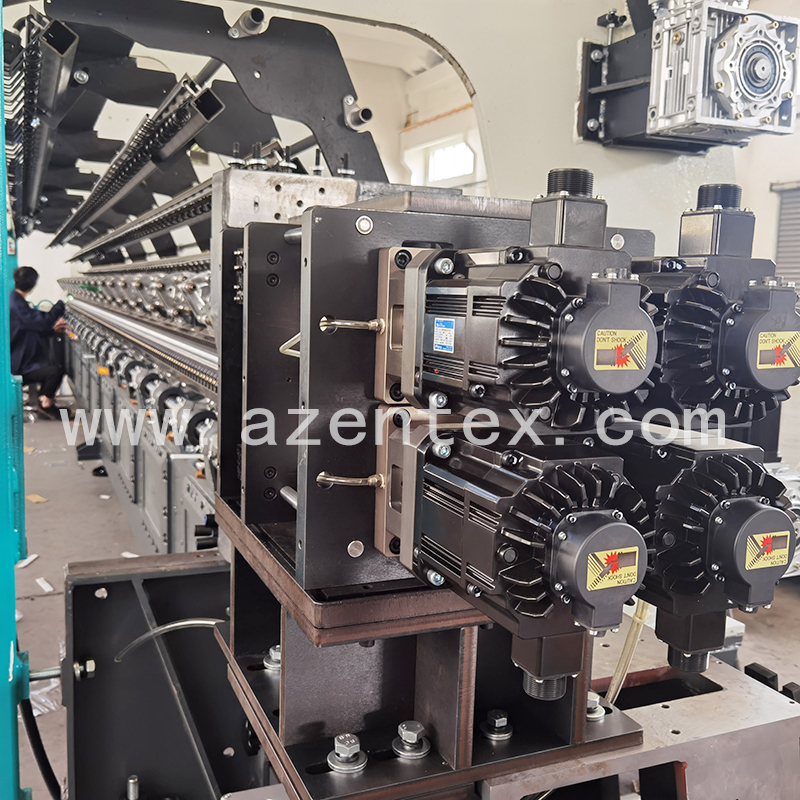

A High-Performance, Versatile, and Cost-Effective Warp Knitting Machine Manufactured by

A-ZEN, the HTS4EL is a standout among warp knitting machines, renowned for its exceptional performance (EL System) and compatibility.

![HTS4EL HTS4EL]()

This machine offers remarkable value for various applications in the textile industry, including outerwear, curtains, sofa fabrics, premium wall coverings, and automotive interior fabrics.

The HTS4EL is available in different working widths, such as 186", 218", 240", 290", and 330", with various gauge options like E24 (Needle Spec.: 51.55), E28, and E32, catering to diverse fabric requirements.

Leveraging its electronic lapping movement capabilities, the HTS4EL can produce fabrics with large lapping movements, such as long-pile and turtle-fur fabrics, with a maximum cumulative lateral movement of up to 50 needles. Its versatility makes it suitable for a wide range of fabric applications, ensuring flexibility and efficiency in production.

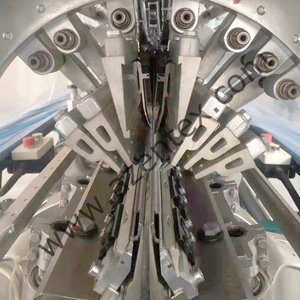

Designs Capacity of the Tricot Warp Knitting Machine HTS4EL

![AZEN HTS4EL AZEN HTS4EL]()

Course Yarn Curtain

![a881e07296f7f3f6f41b2f9ec0427570 a881e07296f7f3f6f41b2f9ec0427570]()

Tulle Curtain

![c0a23ed04339e07a2aa2145e4d53f04d c0a23ed04339e07a2aa2145e4d53f04d]()

Embroderiy-like Effect

Features of the Tricot Warp Knitting Machine HKS4EL

1. Stable Working Performance;

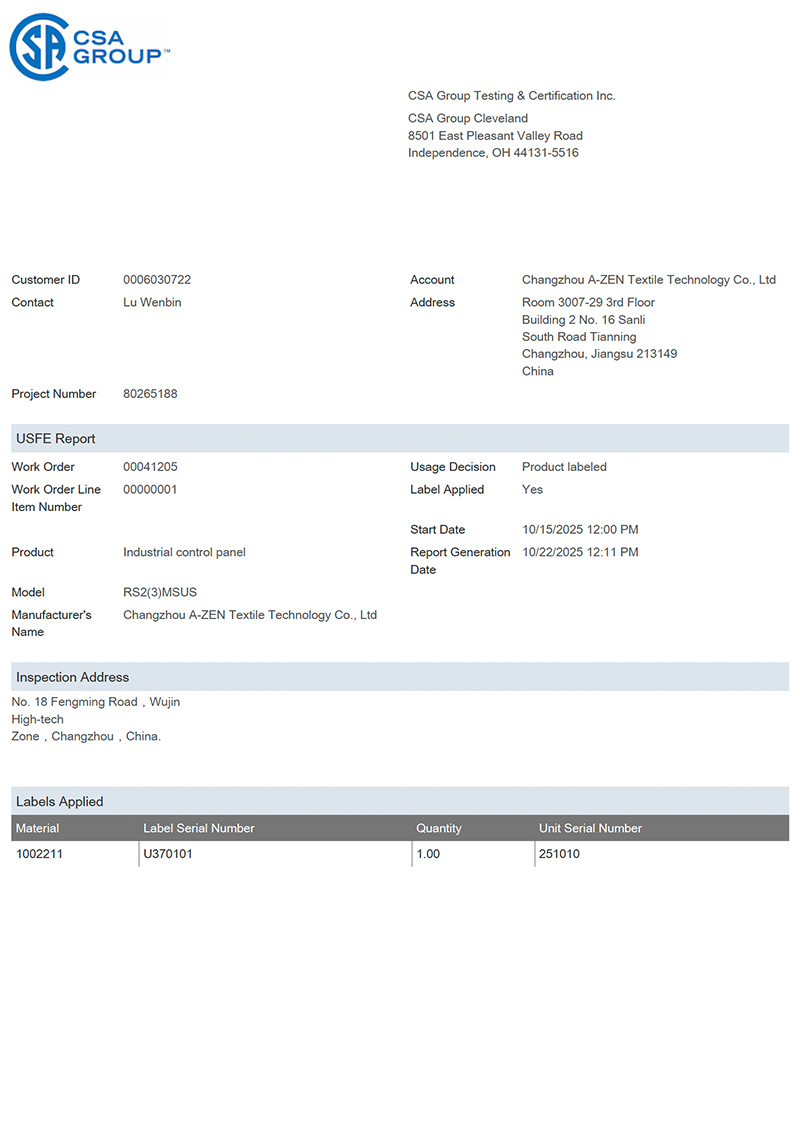

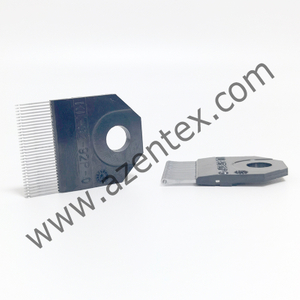

2. Reliable Spare-parts Partners

(1) Needle Elements Suppliers: Groz-Beckert, Saxonia;

(2) EL Drives Suppliers: Mitsubishi, Yaskawa;

(3) Bearing Suppliers: NSK, INA, FAG;

(4) Needle Beds and Bars Material: Reinforced Carbon-fiber Material;

(5) Electrical Elements Suppliers: Schneider, Siemens, Omron, INVT;

(6) Take-up Belt: Bobotex.

3. Overseas Service Team:

Türkiye, India, Egypt, Germany, Indonesia, and Iran.

Original Machine Design & Custom Development

A-ZEN offers tailored machine designs and custom development solutions to meet specific client needs, ensuring optimal performance for diverse textile applications.

![Original-Machine-Design Original-Machine-Design]()

Original Machine Design & Custom Development

![Custom-Development Custom-Development]()

Original Machine Design & Custom Development

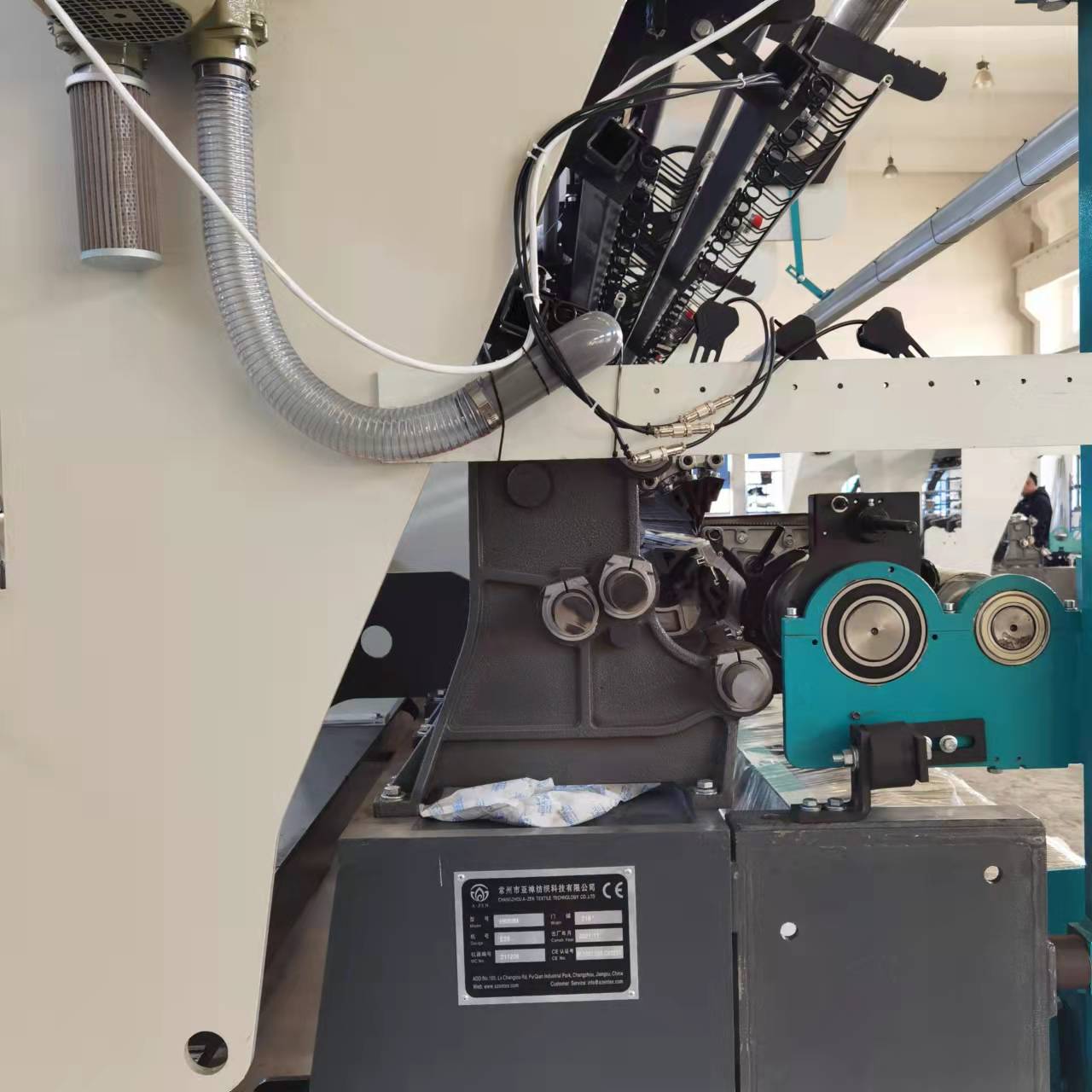

ISO-Standard Assembly and Quality Inspection

![Quality-Control-During-Assembly Quality-Control-During-Assembly]()

Quality Control During Assembly

![Quality-Control-During-Assembly-2 Quality-Control-During-Assembly-2]()

Quality Control During Assembly

![Quality-Control-During-Assembly-3 Quality-Control-During-Assembly-3]()

Quality Control During Assembly

![Quality-Control-During-Assembly-4 Quality-Control-During-Assembly-4]()

Quality Control During Assembly

Professional Packing and Shipping Team

![Warp-Knitting-Machine-Delivery Warp-Knitting-Machine-Delivery]()

Warp Knitting Machine Delivery

![Seaworthy-Package Seaworthy-Package]()

Seaworthy Package

![Professional-Shipping-1 Professional-Shipping-1]()

Professional Shipping

![Professional Shipping Professional Shipping]()

Professional Shipping

Expert After-Sales and Global Service Network

A-ZEN provides local service in India, Türkiye, Egypt, Indonesia, Pakistan, and Iran, with plans to expand further. Our global service teams ensure timely support and maintenance.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Bosanski

Български

ქართული

Lietuvių

Wikang Tagalog