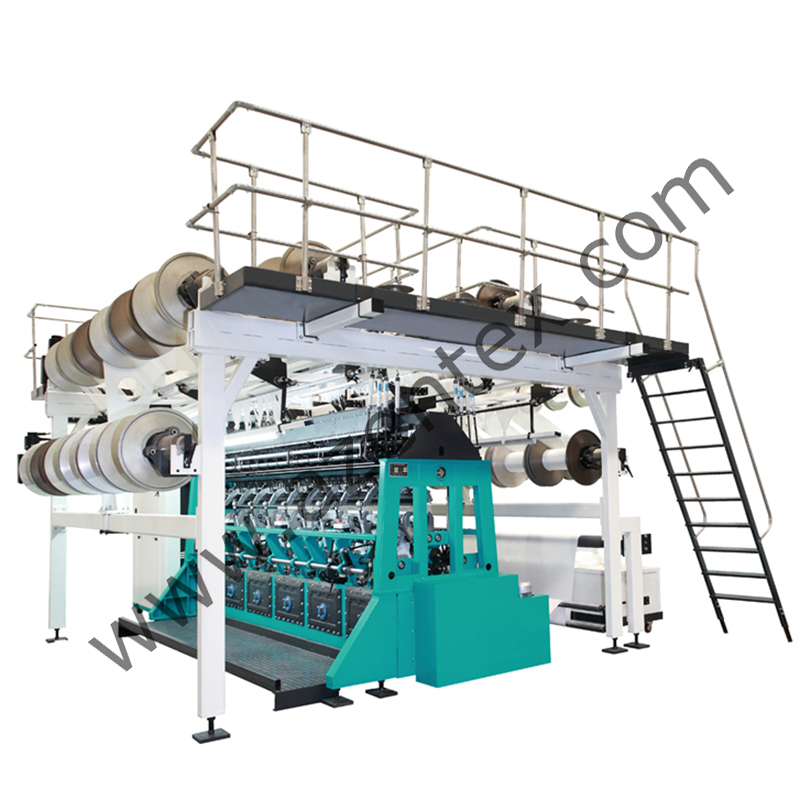

A-ZEN is a professional manufacturer that insists on providing the best quality double needle bar sports net warp knitting machine to customers.

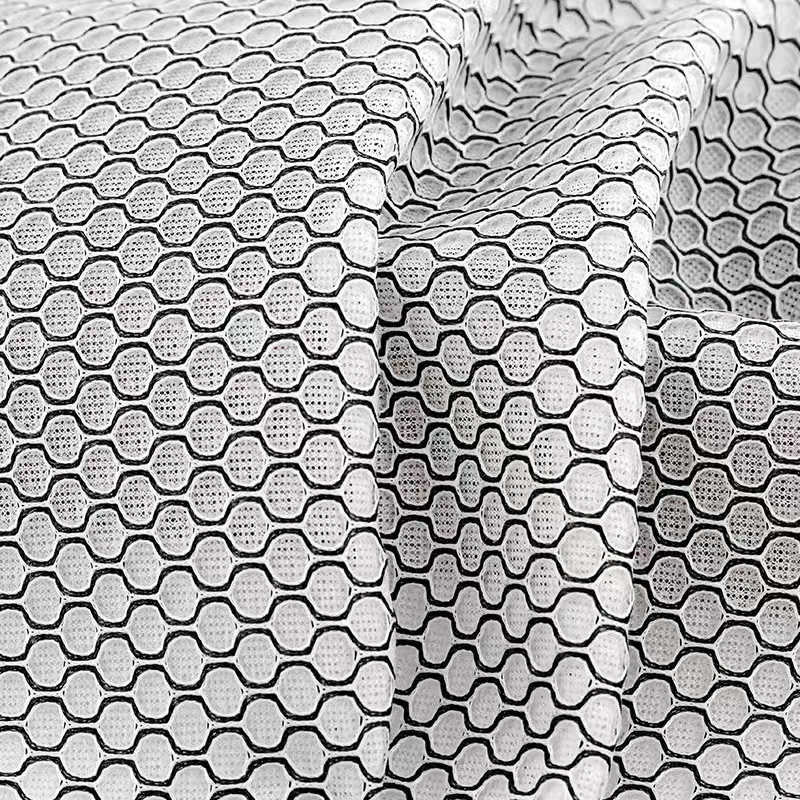

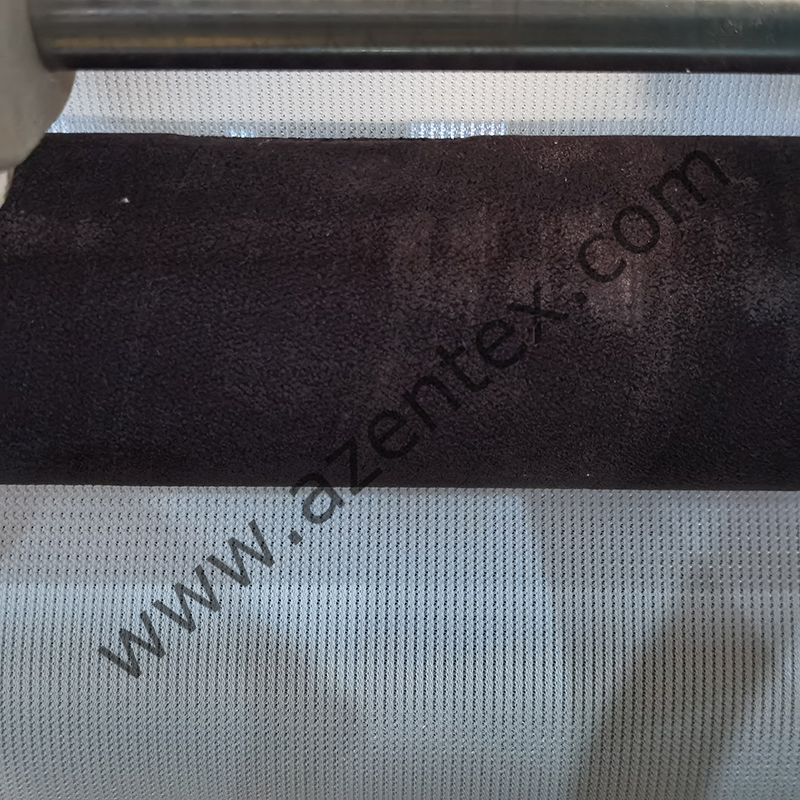

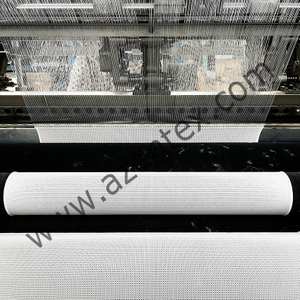

Double-needle bar sports net warp knitting machine is a high-performance warp knitting machine that is specifically designed for producing various warp-knitted mesh fabrics like sports shoe upper fabrics, automotive seat covers, health care, mattresses, and so on.

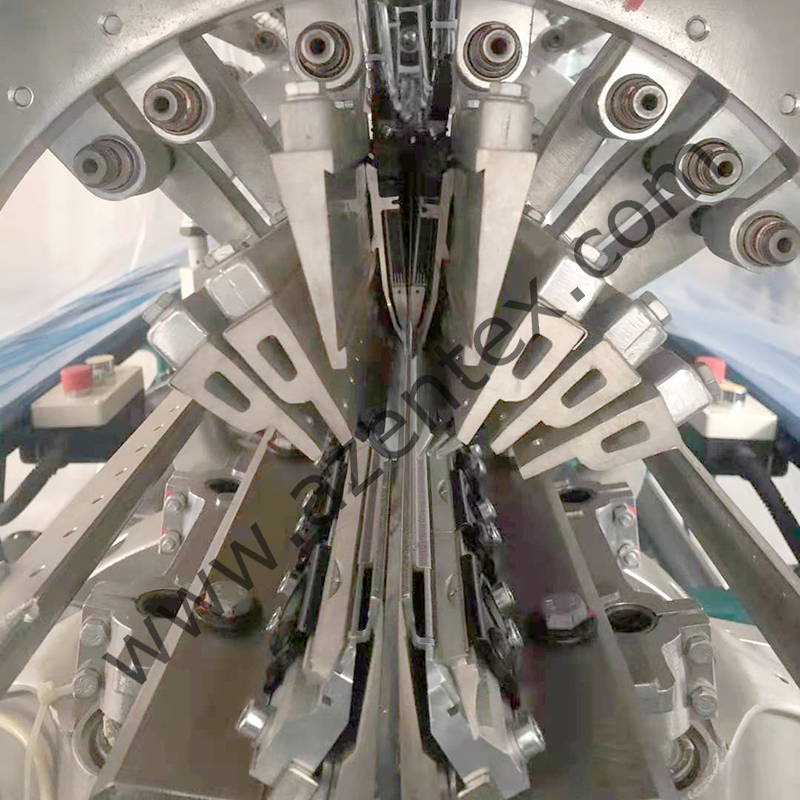

The machine features a double needle bar design, which enables it to produce two different mesh structures simultaneously, thus providing high efficiency and flexibility. Additionally, the machine utilizes advanced computer control technology, which allows for precise weaving and adjustments, ensuring the quality and consistency of the fabric.

Unlike traditional models, the RD7EL adopts reinforced materials and upgraded design, enabling stable operation at nearly 1,000 rpm when running with double monofilament yarns: GB4 and GB5. What sets it apart from competitors is its adjustable large-stroke mechanism. Users can easily switch stroke settings based on different fabric requirements—making material development faster, production more efficient, and operations much more user-friendly.

As always, A-ZEN equips its machines with durable components and energy-saving designs, ensuring outstanding cost-performance, reduced maintenance costs, and long service life.

Machine Features:

1. Stable Working Performance;

2. Reliable Spare-parts Partners

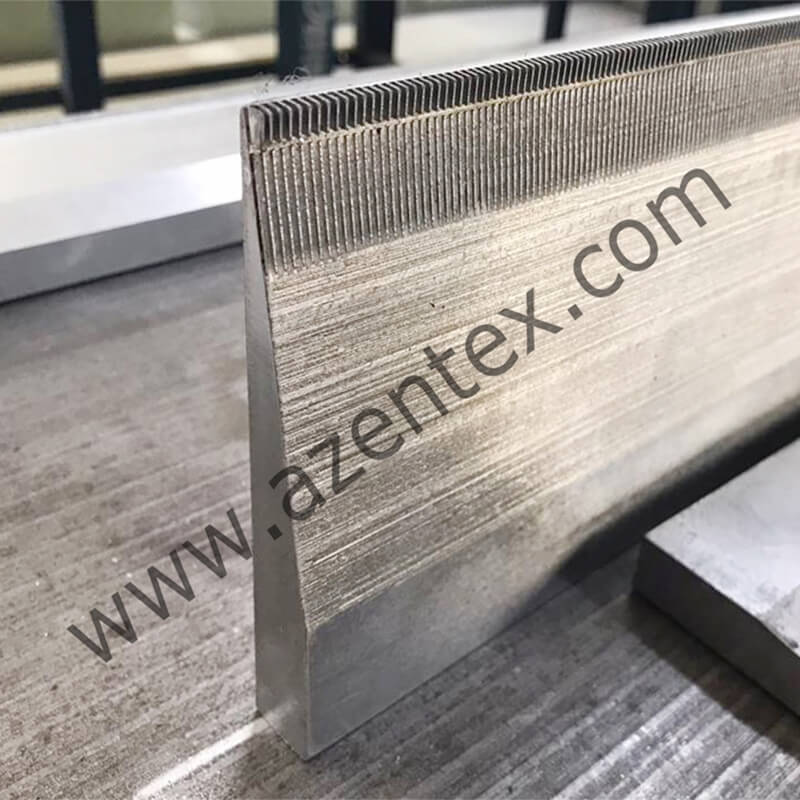

(1) Needle Elements Suppliers: Groz-Beckert, Saxonia;

(2) EL Drives Suppliers: Mitsubishi, Nidec;

(3) Bearing Suppliers: NSK, INA, FAG;

(4) Needle Beds and Bars Material: Magnalium Material (Aviation Aluminum materials are widely used);

(5) Electrical Elements Suppliers: Schneider, Siemens, Omron, INVT;

(6) Take-up Belt: Bobotex.

3. Overseas Service Team:

Türkiye, India, Egypt, Indonesia, and Iran.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Bosanski

Български

ქართული

Lietuvių

Wikang Tagalog