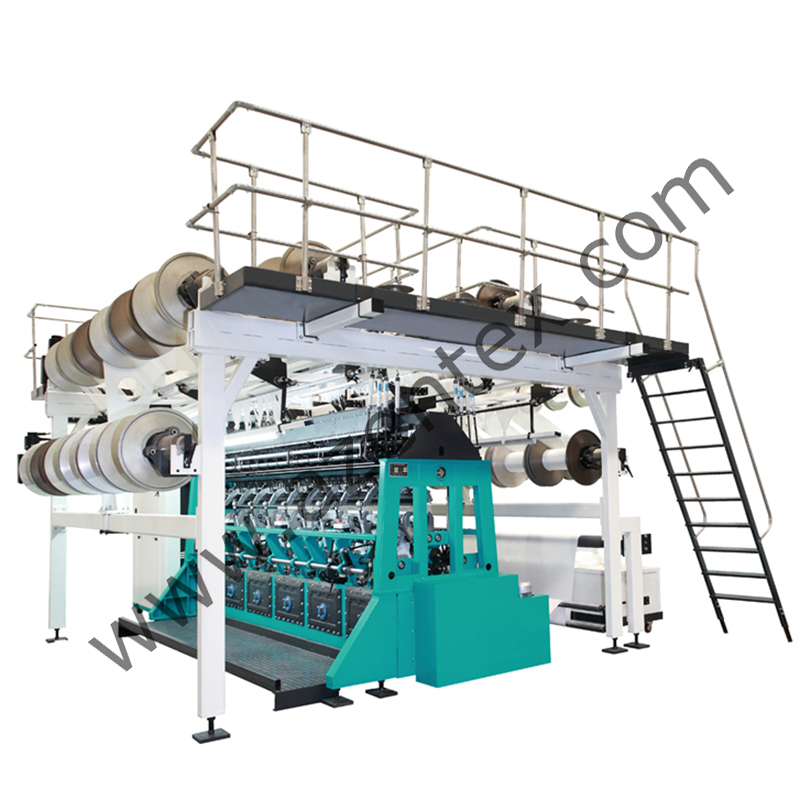

![Air Mesh Spacer Designs Air Mesh Spacer Designs]() Double-needle Bar Raschel Warp Knitting Machine is a marketable warp knitting machine, and it has a wide range of applications.

Double-needle Bar Raschel Warp Knitting Machine is a marketable warp knitting machine, and it has a wide range of applications.

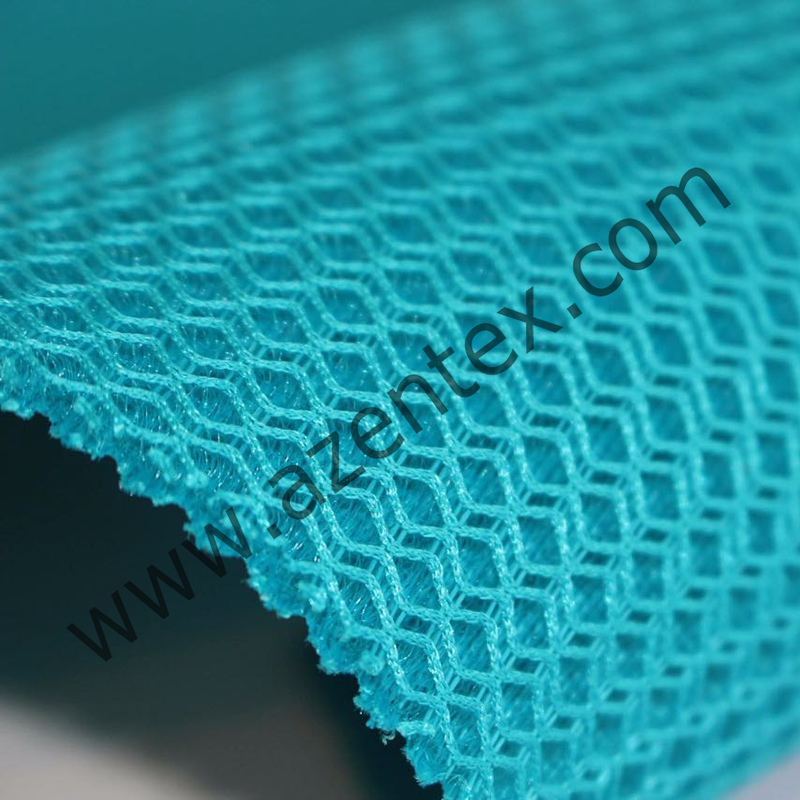

As the flagship product of double-needle bar machines, RD7-EL is designed to produce air-mesh spacer textile, which is also called the 3D warp-knitted textiles, such as sports shoe uppers, automotive interiors, mattresses, spacer fabrics for backpacks, and other spacer textiles.

RD7-EL Raschel double-needle bar warp knitting machine has 7 ground bars, and the working speed could achieve 850rpm. Because of the EL drive system, the RD7-EL machine has a strong ability in the pattern development aspect.

Elevate your shoe upper production to new heights with the RDJ7/1 Double Needle Bar Jacquard Warp Knitting Machine by A-ZEN. Engineered to perfection, this state-of-the-art equipment delivers unparalleled quality, efficiency, and reliability, making it the ultimate choice for manufacturers seeking to produce premium-grade jacquard shoe uppers.

Machine Features:

![AZEN Warp Knitting System AZEN Warp Knitting System]()

1. Stable Working Performance & High Productivity;

2. Reliable Spare-parts Partners

(1) Needle Elements Suppliers: Groz-Beckert, Saxonia;

(2) EL Drives Suppliers: Mitsubishi, Nidec, Yaskawa;

(3) Bearing Suppliers: NSK, INA, FAG, FAG;

(4) Needle Beds and Bars Material: Magnalium Material;

(5) Electrical Elements Suppliers: Schneider, Siemens, Omron, INVT;

(6) Take-up Belt: Bobotex;

(7) Others: Durable Material and Market-tested Brands.

3. Overseas Service Team:

Türkiye, India, Egypt, Indonesia, Pakistan, and Iran.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Bosanski

Български

ქართული

Lietuvių

Wikang Tagalog