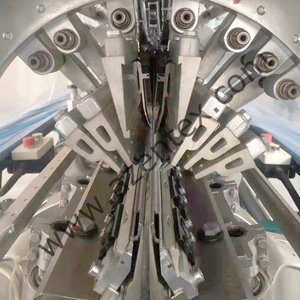

Warp Knitting Machine Spare Parts Video

A-ZEN Push Rod Overview

A-ZEN Push Rods are engineered for Tricot (HKS/KS) and Double Needle Bar Raschel machines. Available in D20/D25 carbon fiber with D18 imported alloy heads, they deliver ultra-low weight, high strength, and rustproof durability at speeds exceeding 2500 RPM.

Key Features

Carbon Fiber Shaft: 70% lighter than steel, zero fatigue failure.

Imported Alloy Head: D18, electroplated, 100,000+ cycle lifespan.

Custom Lengths: Any size — precision-cut to your machine specs.

RD-Series Upgrade: Electroplated head for rustproof, high-load performance.

Applications

Tricot Machines: High-speed lace, velvet, mosquito nets.

Double Needle Bar: Air mesh, 3D spacer, blankets, seamless wear.

High-Load RD Series: Heavy-duty industrial & automotive fabrics.

Product Images

FAQ

Q: Can you produce custom-length push rods?

A: Yes! Confirm head size (D18) and shaft length — we CNC-cut to your exact specs.

Q: Is your push rod quality reliable?

A: We use them in our own machines. Carbon fiber + imported alloy head = zero failure in 24/7 operation. 100% repeat orders.

Q: Do you provide other warp knitting spare parts?

A: Yes! Full range for Tricot, Double Needle Bar, and all major brands — needles, bearings, beds, electronics.

About A-ZEN Textile Technology

CHANGZHOU A-ZEN TEXTILE TECHNOLOGY CO., LTD. is a leading manufacturer of warp knitting machines and spare parts based in Changzhou, China. Over the past 15 years, we’ve delivered nearly 1,000 machines worldwide, including Multi-bar Raschel, Jacquard, Tricot, Double-Needle Bar, and Warping systems.

Driven by innovation, responsibility, and collaboration, A-ZEN serves markets in China, Turkey, India, Egypt, Indonesia, Bangladesh, Brazil, Pakistan, Iran, Kenya, Thailand, Mexico, and beyond.

![A-ZEN Advanced Manufacturing Facility]()

Manufacturing Factories:

Four advanced workshops: two for machines, one for fabric testing, one for precision spare parts (CNC-machined needle beds, guide bars, sinkers).

New machines undergo rigorous in-house fabric trials before market launch.

Global Exhibition:

![A-ZEN at ITMA Global Exhibition]()

We exhibit at ITMA, ITM, ITME, and more — showcasing innovation and gathering customer insights.

Communication and cooperation drive every showcase.

Customer Training

![A-ZEN On-site Technical Training]() Technical support is central to our service. We provide manuals, online guides, videos, and on-site training in over 10 countries. Local teams operate in Turkey, India, Pakistan, Indonesia, Iran, and Egypt — earning high market trust.

Technical support is central to our service. We provide manuals, online guides, videos, and on-site training in over 10 countries. Local teams operate in Turkey, India, Pakistan, Indonesia, Iran, and Egypt — earning high market trust.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Bosanski

Български

ქართული

Lietuvių

Wikang Tagalog

Technical support is central to our service. We provide manuals, online guides, videos, and on-site training in over 10 countries. Local teams operate in Turkey, India, Pakistan, Indonesia, Iran, and Egypt — earning high market trust.

Technical support is central to our service. We provide manuals, online guides, videos, and on-site training in over 10 countries. Local teams operate in Turkey, India, Pakistan, Indonesia, Iran, and Egypt — earning high market trust.