- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

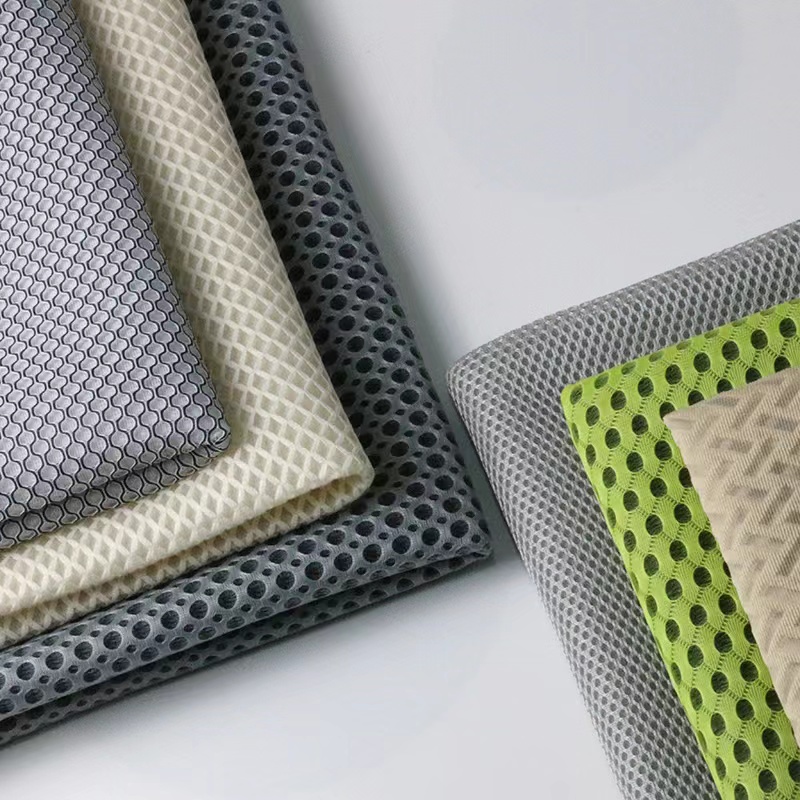

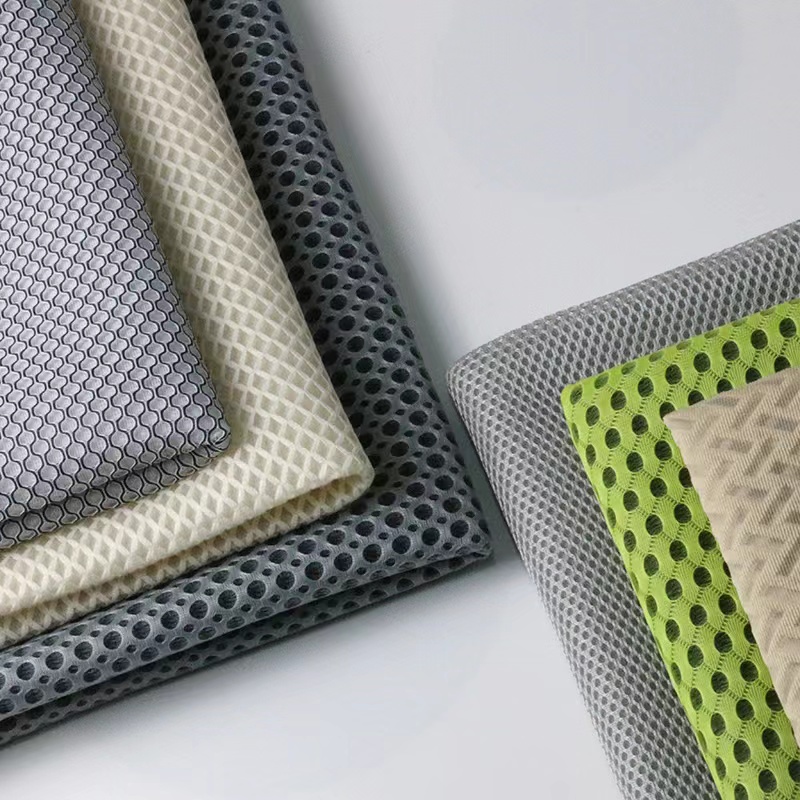

The A-ZEN RD6-EL is engineered to produce high-quality 3D air-mesh spacer fabrics, also known as three-dimensional mesh textiles, widely used in sports shoe uppers, automotive seats, mattress textiles, and other applications. These fabrics offer thicknesses from 1mm to 50mm, ensuring versatility for various industries.

Introduced in 2014, the A-ZEN RD6-EL double needle bar raschel machine has undergone continuous improvements in its warp knitting mechanical structure and electronic components. With market-tested technology and durable parts, it is a top choice among A-ZEN’s warp knitting machines.

Featuring 6 ground bars, a knock-over comb bar distance of 2-12mm, and available working widths of 138" and 210", the RD6-EL delivers exceptional performance. A-ZEN also offers other models, including RD7, RDJ5/1, RDJ4/2, and AZ2885.

3D Spacer Fabric

Air-Mesh Textile

Mattress Textile

| 1 | Working Width | 138", 210" |

| 2 | Machine Gauge | E18, E22, E24, E28 |

| 3 | Working Speed | 50-750 RPM (Depends on Yarn and Designs) |

| 4 | Knock-over Comb Bar Distance | 2-12mm |

| 5 | Bars/Knitting Elements | 2 needle bars with latch needle units (individual needle and needle block optional), 2 knock-over comb bars, 6 ground bars |

| 6 | Pattern Drive System | Pattern Discs Drive or EL Drive (Optional) |

| 7 | Yarn Let-off Device | EBC Yarn Let-off System |

| 8 | Fabric Take-up | Electronic Fabric Take-up System |

| 9 | Batching Device | Electronic Batching Device |

| 10 | Laser Stop Detector and Online Service Program | Optional |

| 11 | Air Blower Device | Optional |

| 12 | In-house Test | Optional |

Ensures consistent output for 3D mesh textiles with reliable operation.

Sourced from top suppliers:

Needle Elements: Groz-Beckert, Saxonia

EL Drives: Mitsubishi, Nidec, Yaskawa

Bearings: NSK, INA, FAG

Needle Beds and Bars: Magnalium Material

Electrical Elements: Schneider, Siemens, Omron, INVT

Take-up Belt: Bobotex

Available in Türkiye, India, Egypt, Indonesia, and Iran.

The EBC yarn let-off system reduces energy consumption by up to 15%.

Mitsubishi EL drives ensure accurate 3D mesh patterns for diverse applications.

Magnalium needle beds and NSK bearings enhance machine longevity.

The RD6-EL produces lightweight, breathable air-mesh fabrics, ideal for high-performance sports shoes, offering flexibility in design and superior comfort.

Our 3D spacer fabrics provide excellent durability and ventilation, enhancing comfort for automotive upholstery while meeting eco-friendly standards.

With thicknesses up to 50mm, RD6-EL fabrics ensure optimal air circulation and pressure resistance for premium mattress production.

A leading sports shoe manufacturer in Türkiye used the A-ZEN RD6-EL to produce lightweight, breathable 3D air-mesh fabrics, reducing production time by 20% while maintaining high quality. "The RD6-EL's reliability and A-ZEN's technical support have been game-changers for our production line," says their production manager.

An automotive upholstery supplier in India leverages the RD6-EL to create durable, ventilated seat fabrics, meeting stringent industry standards and enhancing passenger comfort.

Individual Latch Needles

Block Latch Needles

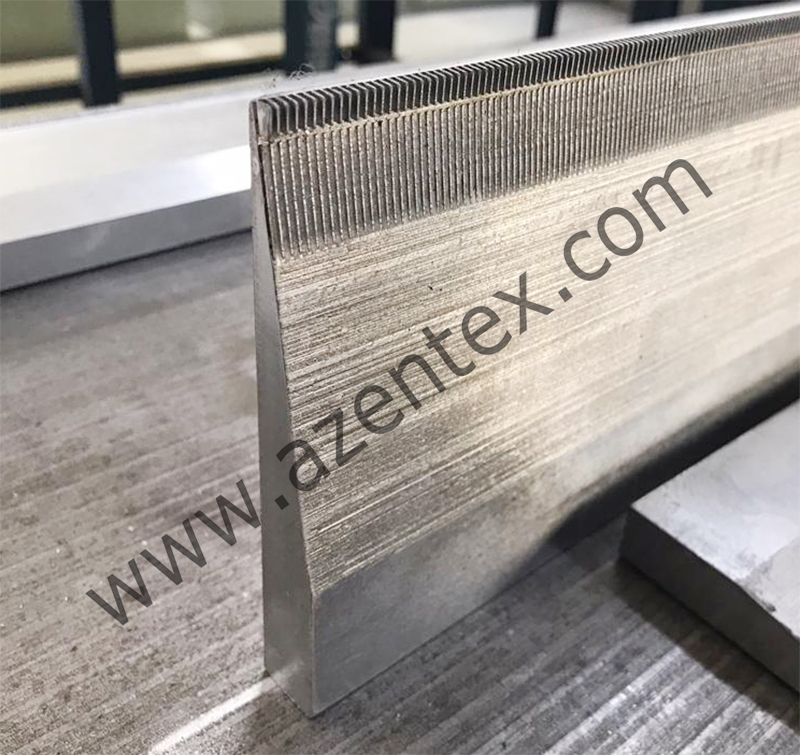

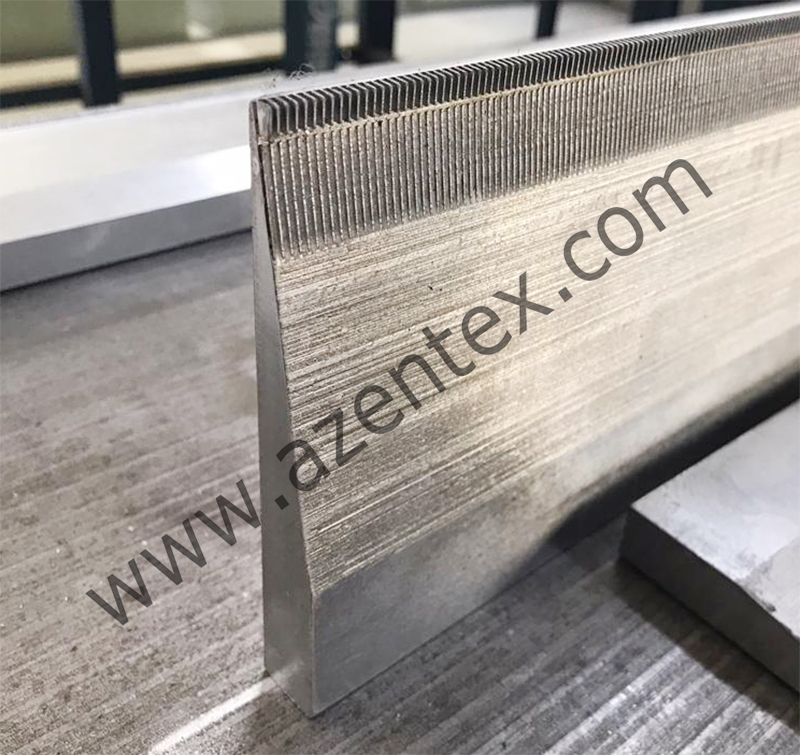

Knock-over Comb Bar

Guide Ground Bar

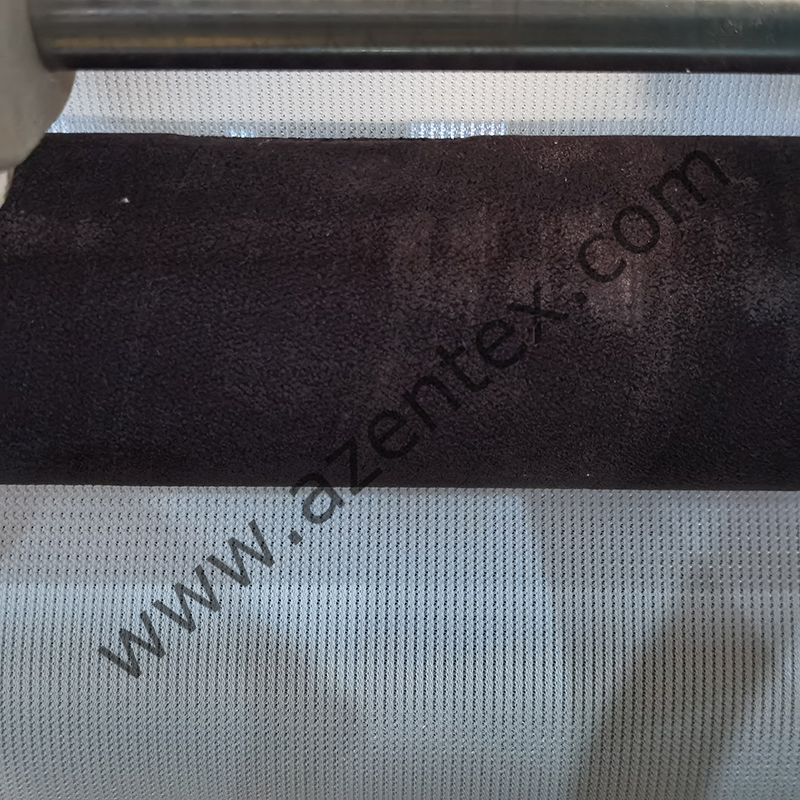

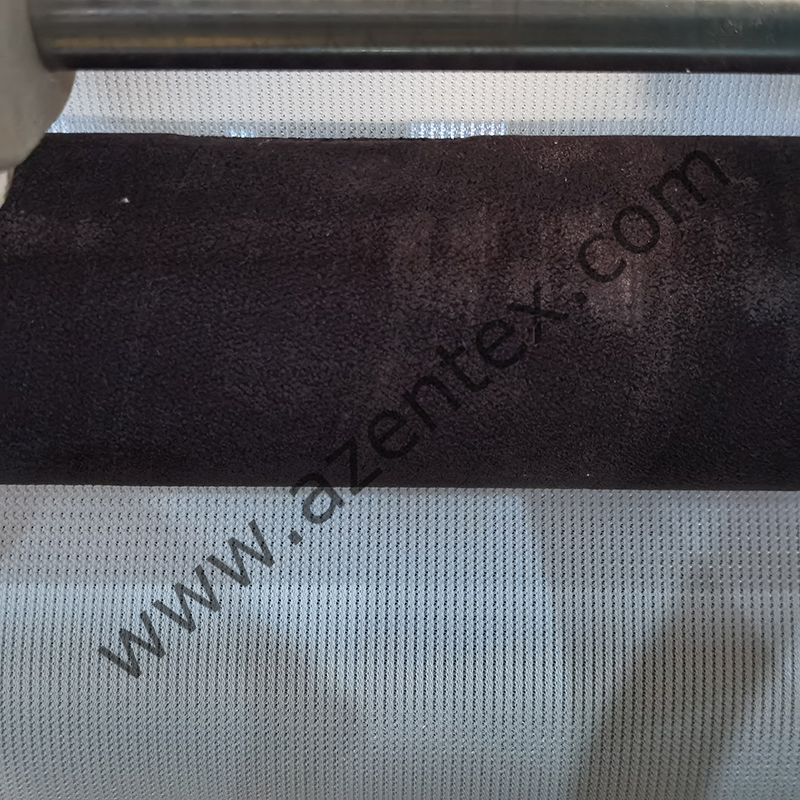

Air-Mesh Fabric

Customer's Production Factory

Overseas Machine Delivery

Watch the RD6-EL in action producing air-mesh sports shoe textiles in Türkiye, 2021.

Warp Knitting Machine Delivery

Seaworthy Package

| Model | Working Width | Speed (RPM) | Applications |

|---|---|---|---|

| RD6-EL | 138", 210" | 600-750 | 3D spacer fabrics, sports shoes, automotive seats |

| RD7 | 138", 200" | 500-700 | General warp knitted fabrics |

The RD6-EL’s energy-efficient design reduces power consumption by up to 15%, and its compatibility with eco-friendly yarns supports sustainable textile manufacturing, meeting modern environmental standards.

The RD6-EL double needle bar warp knitting machine operates at a stable speed of 600-750 RPM, depending on yarn and design specifications.

Supported by an experienced installation and R&D team

Uses branded electrical and imported mechanical parts for reliability

Each machine is rigorously tested before delivery

Continuous improvements based on customer feedback ensure stable, high-quality performance

The RD6-EL supports a wide range of yarns, including polyester, nylon, and blended fibers, ensuring versatility for 3D spacer fabric production.

Regular maintenance includes cleaning needle beds, checking EL drives, and following our detailed operation manual. A-ZEN’s service teams offer ongoing support.

We provide local service in India, Türkiye, Egypt, Indonesia, Pakistan, and Iran, with plans to expand further. Additionally, we offer detailed operation manuals and online technical support for efficient machine adjustments.

Contact A-ZEN today to learn how the RD6-EL can enhance your textile manufacturing. Request a Quote or schedule a demo.

A-ZEN operates four workshops: two dedicated to warp knitting and warping machines, and two for fabric production and spare parts manufacturing. New machines are thoroughly tested in our fabric knitting factory before market release. Spare parts, including compound needle beds, tongue needle beds, needle guide bars, sinker beds, and latch needle beds, are produced using CNC machines, compatible with both Chinese and German warp knitting machines.

We participate in global textile machinery exhibitions such as ITMA, ITM, and ITME, showcasing our latest technology and cost-effective products. These events allow us to gather customer feedback and refine our machines to meet market demands.

Technical support is a cornerstone of our services. We provide comprehensive training through professional manuals, online guides, video tutorials, and on-site training in over 10 countries, including Turkey, India, Pakistan, Indonesia, Iran, and Egypt. Our timely and professional support has earned a strong reputation globally.

The A-ZEN RD6-EL is engineered to produce high-quality 3D air-mesh spacer fabrics, also known as three-dimensional mesh textiles, widely used in sports shoe uppers, automotive seats, mattress textiles, and other applications. These fabrics offer thicknesses from 1mm to 50mm, ensuring versatility for various industries.

Introduced in 2014, the A-ZEN RD6-EL double needle bar raschel machine has undergone continuous improvements in its warp knitting mechanical structure and electronic components. With market-tested technology and durable parts, it is a top choice among A-ZEN’s warp knitting machines.

Featuring 6 ground bars, a knock-over comb bar distance of 2-12mm, and available working widths of 138" and 210", the RD6-EL delivers exceptional performance. A-ZEN also offers other models, including RD7, RDJ5/1, RDJ4/2, and AZ2885.

3D Spacer Fabric

Air-Mesh Textile

Mattress Textile

| 1 | Working Width | 138", 210" |

| 2 | Machine Gauge | E18, E22, E24, E28 |

| 3 | Working Speed | 50-750 RPM (Depends on Yarn and Designs) |

| 4 | Knock-over Comb Bar Distance | 2-12mm |

| 5 | Bars/Knitting Elements | 2 needle bars with latch needle units (individual needle and needle block optional), 2 knock-over comb bars, 6 ground bars |

| 6 | Pattern Drive System | Pattern Discs Drive or EL Drive (Optional) |

| 7 | Yarn Let-off Device | EBC Yarn Let-off System |

| 8 | Fabric Take-up | Electronic Fabric Take-up System |

| 9 | Batching Device | Electronic Batching Device |

| 10 | Laser Stop Detector and Online Service Program | Optional |

| 11 | Air Blower Device | Optional |

| 12 | In-house Test | Optional |

Ensures consistent output for 3D mesh textiles with reliable operation.

Sourced from top suppliers:

Needle Elements: Groz-Beckert, Saxonia

EL Drives: Mitsubishi, Nidec, Yaskawa

Bearings: NSK, INA, FAG

Needle Beds and Bars: Magnalium Material

Electrical Elements: Schneider, Siemens, Omron, INVT

Take-up Belt: Bobotex

Available in Türkiye, India, Egypt, Indonesia, and Iran.

The EBC yarn let-off system reduces energy consumption by up to 15%.

Mitsubishi EL drives ensure accurate 3D mesh patterns for diverse applications.

Magnalium needle beds and NSK bearings enhance machine longevity.

The RD6-EL produces lightweight, breathable air-mesh fabrics, ideal for high-performance sports shoes, offering flexibility in design and superior comfort.

Our 3D spacer fabrics provide excellent durability and ventilation, enhancing comfort for automotive upholstery while meeting eco-friendly standards.

With thicknesses up to 50mm, RD6-EL fabrics ensure optimal air circulation and pressure resistance for premium mattress production.

A leading sports shoe manufacturer in Türkiye used the A-ZEN RD6-EL to produce lightweight, breathable 3D air-mesh fabrics, reducing production time by 20% while maintaining high quality. "The RD6-EL's reliability and A-ZEN's technical support have been game-changers for our production line," says their production manager.

An automotive upholstery supplier in India leverages the RD6-EL to create durable, ventilated seat fabrics, meeting stringent industry standards and enhancing passenger comfort.

Individual Latch Needles

Block Latch Needles

Knock-over Comb Bar

Guide Ground Bar

Air-Mesh Fabric

Customer's Production Factory

Overseas Machine Delivery

Watch the RD6-EL in action producing air-mesh sports shoe textiles in Türkiye, 2021.

Warp Knitting Machine Delivery

Seaworthy Package

| Model | Working Width | Speed (RPM) | Applications |

|---|---|---|---|

| RD6-EL | 138", 210" | 600-750 | 3D spacer fabrics, sports shoes, automotive seats |

| RD7 | 138", 200" | 500-700 | General warp knitted fabrics |

The RD6-EL’s energy-efficient design reduces power consumption by up to 15%, and its compatibility with eco-friendly yarns supports sustainable textile manufacturing, meeting modern environmental standards.

The RD6-EL double needle bar warp knitting machine operates at a stable speed of 600-750 RPM, depending on yarn and design specifications.

Supported by an experienced installation and R&D team

Uses branded electrical and imported mechanical parts for reliability

Each machine is rigorously tested before delivery

Continuous improvements based on customer feedback ensure stable, high-quality performance

The RD6-EL supports a wide range of yarns, including polyester, nylon, and blended fibers, ensuring versatility for 3D spacer fabric production.

Regular maintenance includes cleaning needle beds, checking EL drives, and following our detailed operation manual. A-ZEN’s service teams offer ongoing support.

We provide local service in India, Türkiye, Egypt, Indonesia, Pakistan, and Iran, with plans to expand further. Additionally, we offer detailed operation manuals and online technical support for efficient machine adjustments.

Contact A-ZEN today to learn how the RD6-EL can enhance your textile manufacturing. Request a Quote or schedule a demo.

A-ZEN operates four workshops: two dedicated to warp knitting and warping machines, and two for fabric production and spare parts manufacturing. New machines are thoroughly tested in our fabric knitting factory before market release. Spare parts, including compound needle beds, tongue needle beds, needle guide bars, sinker beds, and latch needle beds, are produced using CNC machines, compatible with both Chinese and German warp knitting machines.

We participate in global textile machinery exhibitions such as ITMA, ITM, and ITME, showcasing our latest technology and cost-effective products. These events allow us to gather customer feedback and refine our machines to meet market demands.

Technical support is a cornerstone of our services. We provide comprehensive training through professional manuals, online guides, video tutorials, and on-site training in over 10 countries, including Turkey, India, Pakistan, Indonesia, Iran, and Egypt. Our timely and professional support has earned a strong reputation globally.